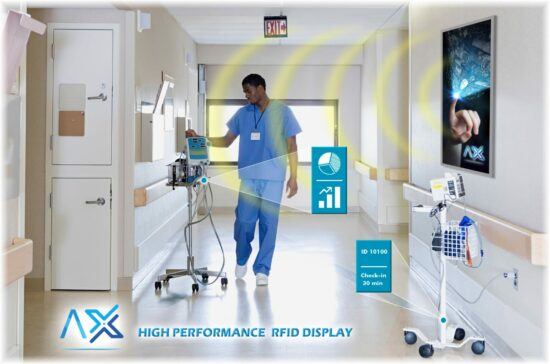

Fixed RFID Advertising Display Gateways

SmartX uses Fixed RFID Display Gateways at chokepoints such as Entry-Exit doors and office corridors for our implementation designs when creating real-time RFID asset tracking systems. This allows us to create a hands-free, automated tracking capability that works for your organization around the clock. This kind of an automated system is always-on and provides a far superior level of inventory accuracy and asset visibility over a manual bar code system.

The concept of using an Advertise RFID Display gateway at a chokepoint is best explained as an egress such as a doorway, or hallway, that all of your assets are forced to move through. RFID Display gateways are strategically positioned in this chokepoint to accurately read all of the passive RFID tags on assets as they move through this area.

For example, let’s imagine an item leaving the receiving asset and moving to the new area. During that movement, let’s assume that there is some sort of a physical bottleneck between these two locations. If we set up a RFID Display reader at this chokepoint we would be able to capture every asset and record it’s new location with a date and timestamp.

One of the details that needs to be worked out with a Passive RFID implementation is the ability to not only scan the asset tag consistently; but, also record the direction that the asset is moving — from the receiving area to the new facility area in this case. This might seem like a trivial point; but, getting directionality working properly is trickier than you think and the benefits are huge.

Audit Trails

RFID Display Gateways are a great way to capture the movement of your assets. The ability to automatically capture and record data every time your asset moves through a gateway is a powerful way to generate an audit trail.

An audit trail is a record of all the lifecycle events, such as movement events, for your particular item which provides a history of that item from its creation to the present day. Maintaining a chronological record that provides evidence of the lifecycle events for an asset is required for many industries and is a powerful tool for any organization.

Start small and grow

Depending upon your needs (and the investment you are ready to make) you can obviously set up as few, or as many, gateways in your facility as you choose. More gateways will provide you with smaller zones and more granular locations — while fewer gateways will provide you a way to easily get started and keep your costs low to test the effectiveness.

Implementing a single RFID gateway in a strategic location might be all that your organization needs; while others will want to break their facility into smaller zones separated by multiple gateways. The key to the system design is that as an asset moves from one zone location to the next it’s forced through a gateway and the new location recorded.

Mounting gateways and defining locations

Our cost-effective RFID solution, the RFID Display Reader, has an unlimited range of applications for many different fields.

- Healthcare and Clinical applications

Know where samples and tests are within your workflow. Keep an inventory of medications and equipment to locate particular items quickly for patients in need. Prevent the misuse of high value assets and equipment by monitoring who has it and where. - School and club applications

Keeping track of equipment for educational purposes, particularly for special populations of students, is tantamount to ensuring safety. Know when and where equipment is checked out and monitor their return.

- Fashion, jewelry, museums, and gallery applications

You don’t need an expensive solution to keep track of highly valued jewelry and fine art. RFID Display Reader and tags track even the most valued assets, preventing theft and unauthorized movement.

Conclusion

RFID-enabled asset management links electronic and physical asset tracking from purchasing through end-of-life. It offers immediate, substantial returns on investment by preventing loss and theft of valuable assets, recovering misplaced, powered-down, and maintaining the integrity of asset information through critical life cycle stages.

By retaining the last known location of the tagged assets in SmartX HUB Platform, the RFID-enabled solution provides inventory location information for assets across the facility. This perpetual inventory not only provides location data to help staff locate assets but creates an efficient method to account for equipment

inventories.