5 Tips for Maximizing Oil & Gas Asset Utilization With RFID

5 Tips for Maximizing Oil & Gas Asset Utilization With RFID Effective asset utilization holds immense significance in the oil

Track asset performance, execute maintenance and service, and maximize uptime with advanced technologies.

Deliver as promised with risk-resilient, reliable, and sustainable logistics operations.

A revolutionary convergence of personal and process safety that improve efficiency, safety and reliability.

Increase visibility and accuracy of the production by providing real-time visibility to product flow

RFID technology accurately tracks the production flow in your production environment. You receive valuable information, allowing you to analyze your production processes. Based on this, it is possible to identify bottlenecks, optimize production routes, and determines JIT strategies for stock management, resulting in significant cost savings.

Give managers better visibility of WIP at various manufacturing stages

Read all items, even within closed boxes, to ensure contents are correctly

Get the right items to the right location at the right time—every time

Bring agility to assembly lines with data that informs operations and customers

Reduce the time it takes to make important supply chain decisions by providing access to real-time information

Keep assembly lines moving with the right material appearing in the right place at the right time, eliminating bottlenecks and

waste. Know the current location and status of all your moving parts and tools, from raw goods to finished products.

By incorporating the right mix of SmartX HUB' tracking solutions, you can have real-time insights to take data-driven actions to run a smarter, leaner production line.

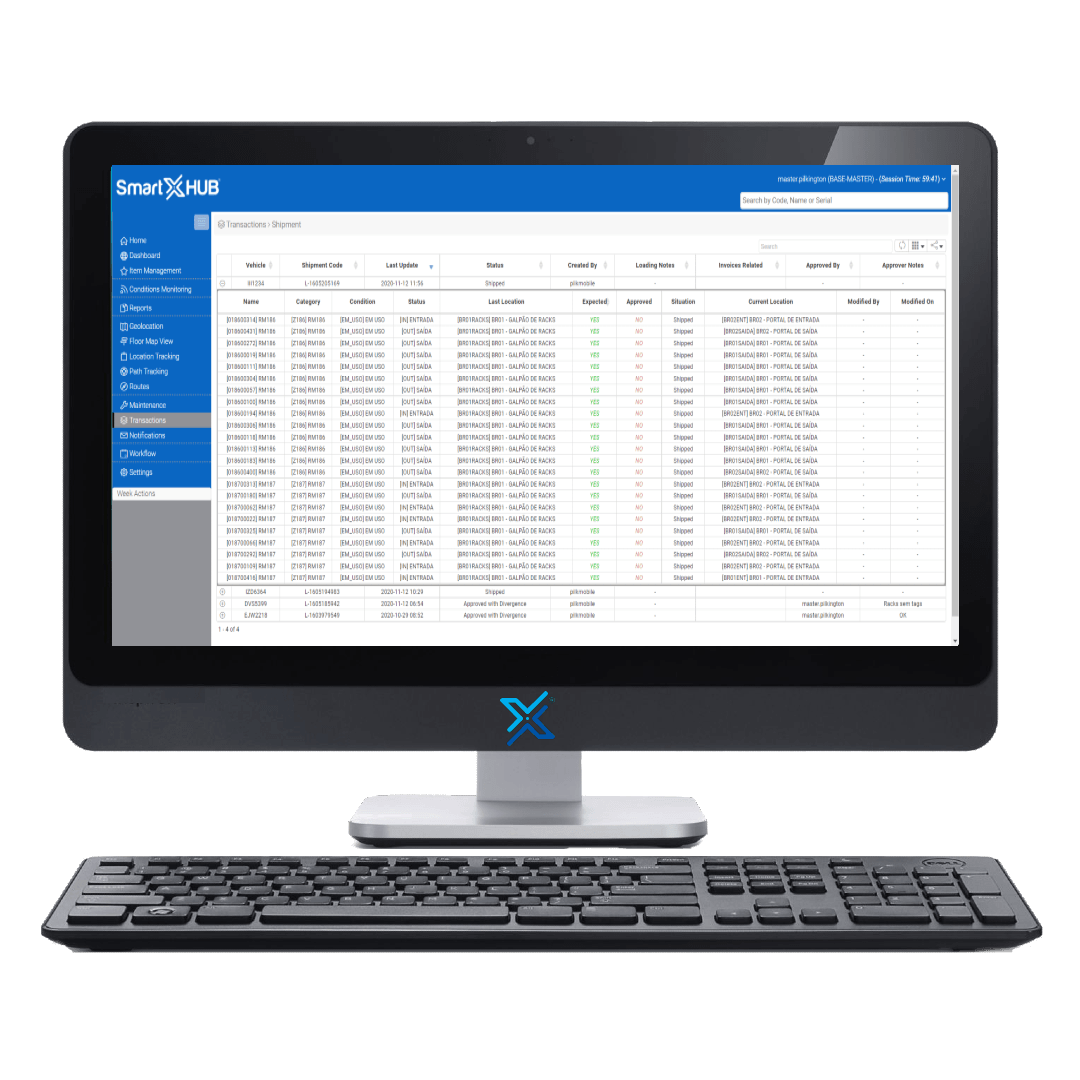

You can avoid errors resulting from improper data logging and labeling by utilizing RFID solutions. Since data from RFID work in progress can be synchronized with other data processing systems (ERP systems), you can visualize the production cycles easily using a single platform.

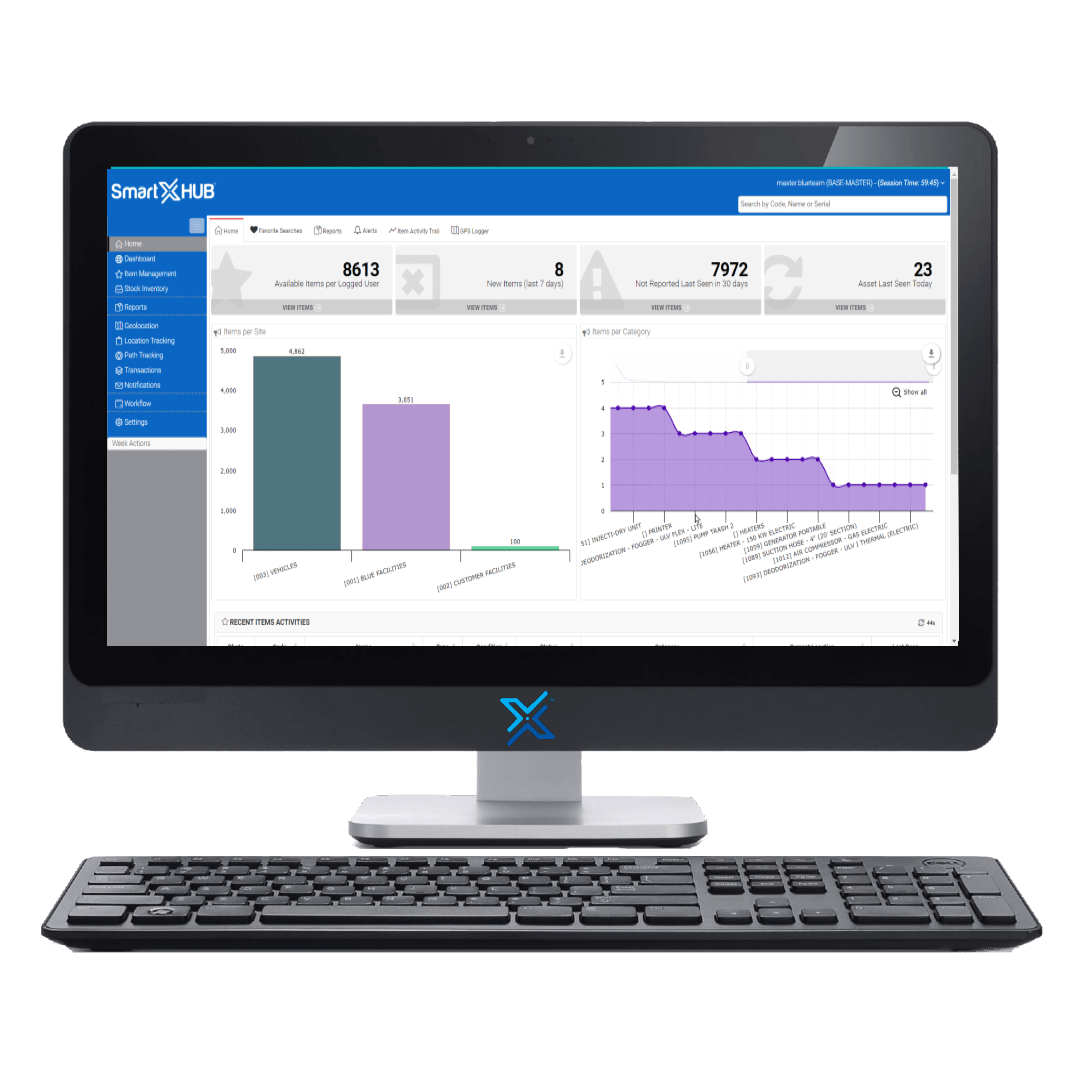

Our RFID Platform has a robust value proposition making it a critical competitive differentiator. Seamless workflow systems bolster ROI through accurate tracking of WIP assets, unlimited real-time WIP inquiries, and automated WIP reports. Such reports inform decision-making processes at the departmental and executive level

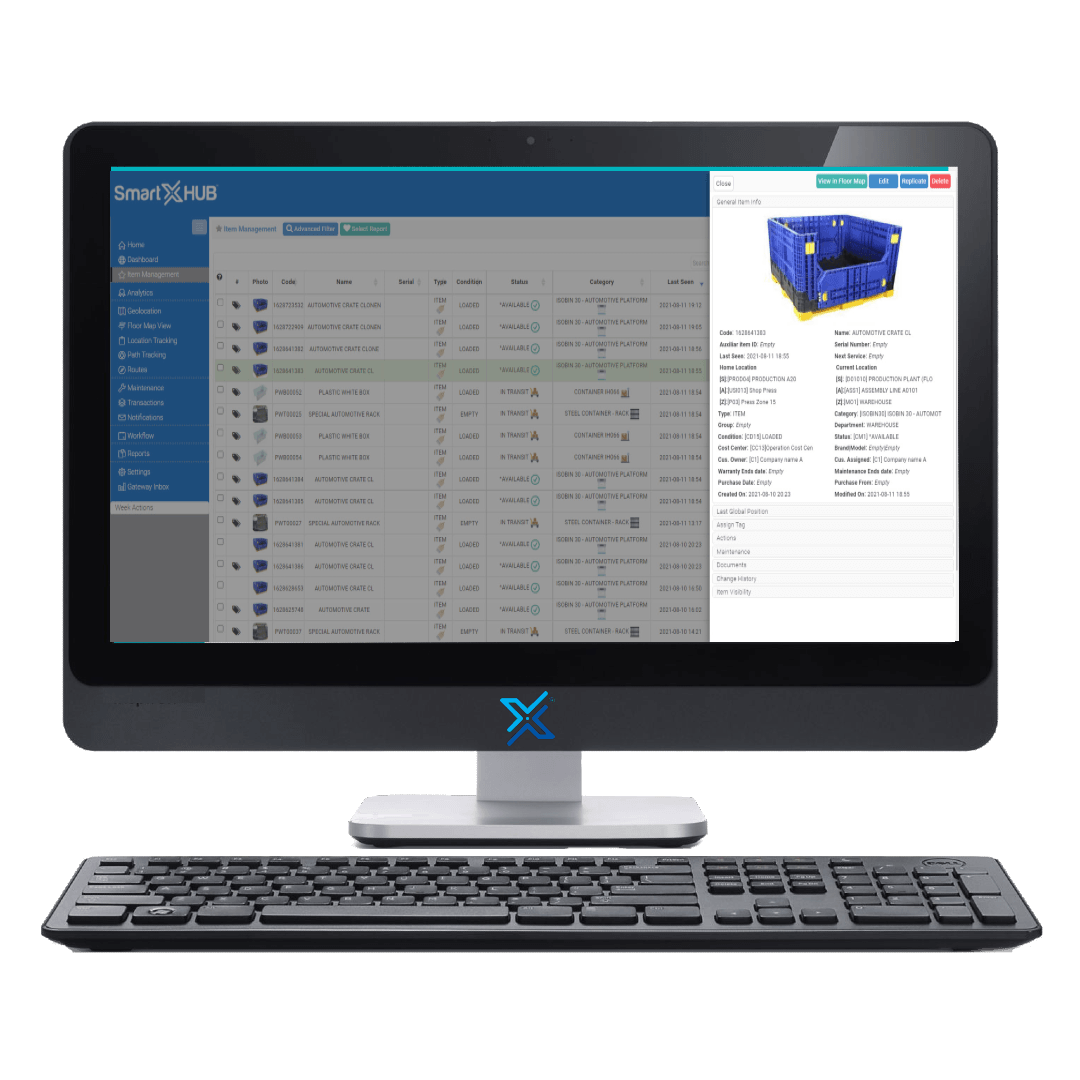

From raw materials to finished product, you need visibility to the entire manufacturing process. SmartX HUB’s production tracking software incorporates automated WIP tracking, giving manufacturers full transparency into manufacturing operations. WIP tracking combined with RFID in manufacturing adds new dimension to visibility throughout the factory floor.

These applications are being implemented not only for tracking reasons, but are driving business value in many innovative ways, including the following:

SmartX HUB RFID provides a way to automatically capture information about the items, people and processes critical to your operations. Many manufacturers have become familiar with RFID in their warehouse, where it can be used to tag and wirelessly track inventory. RFID tags allow materials, finished goods, pallets, shipments and virtually any asset to be identified and located automatically and remotely, without having to manually scan barcodes or have line-of-sight to collect data.

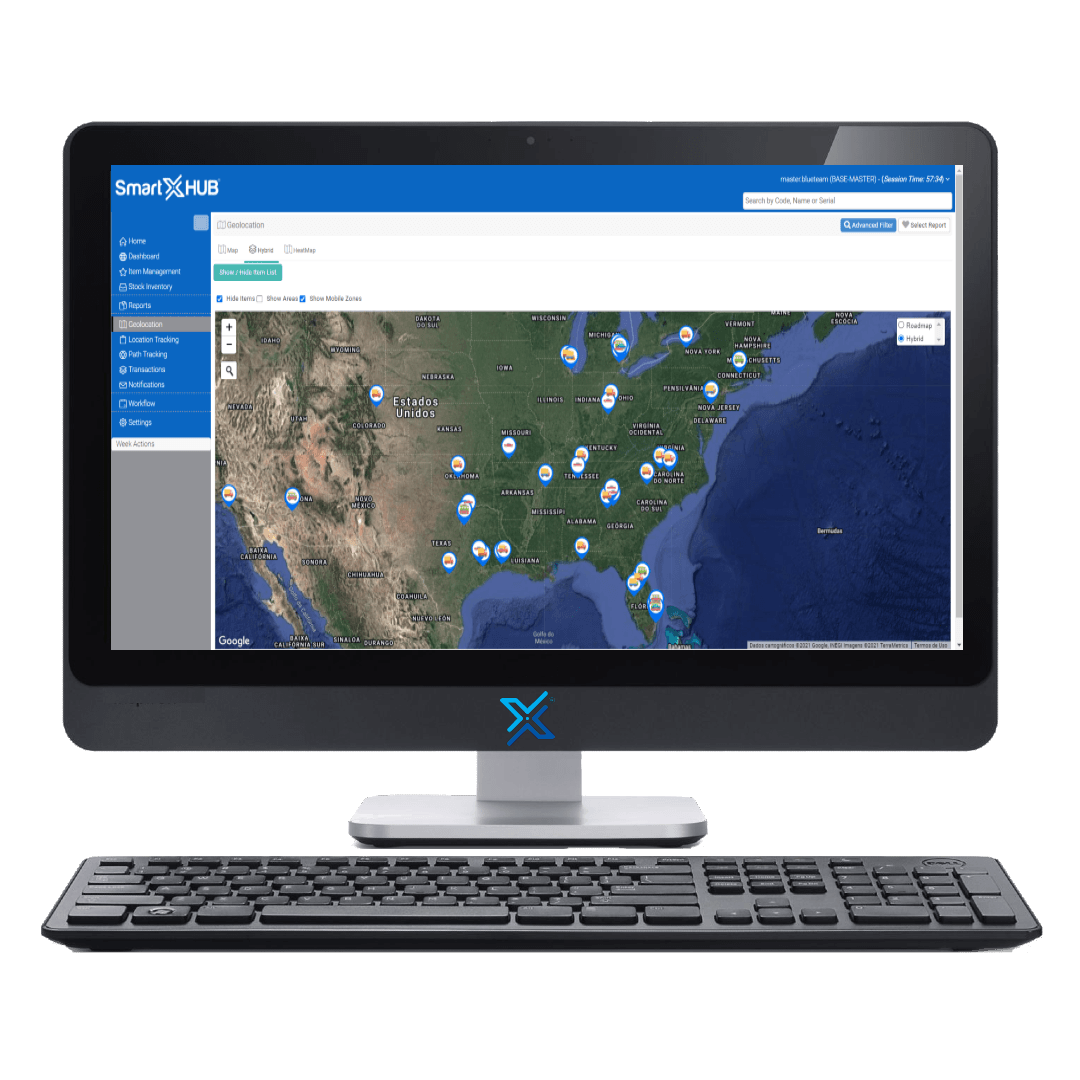

Assets data can be tricky with diverse vendors system and models. SmartX HUB not only connects and acquires data but also harmonizes portfolio O&M data for intelligence. Break down traditional visibility silos to create a unified view across the enterprise.

With real-time movement detection capabilities, you can build more efficient shipping and receiving plans, enforce control, and streamline operations. Optimizing your facility means your equipment and vehicles spend less time waiting and more time working, earning you more value for your investments.

Real-time data about items, pallets, and containers passing through dock doors is collected automatically by shipping and receiving tracking systems. With real-time movement detection capabilities, you can build more efficient shipping and receiving plans, enforce control, and streamline operations.

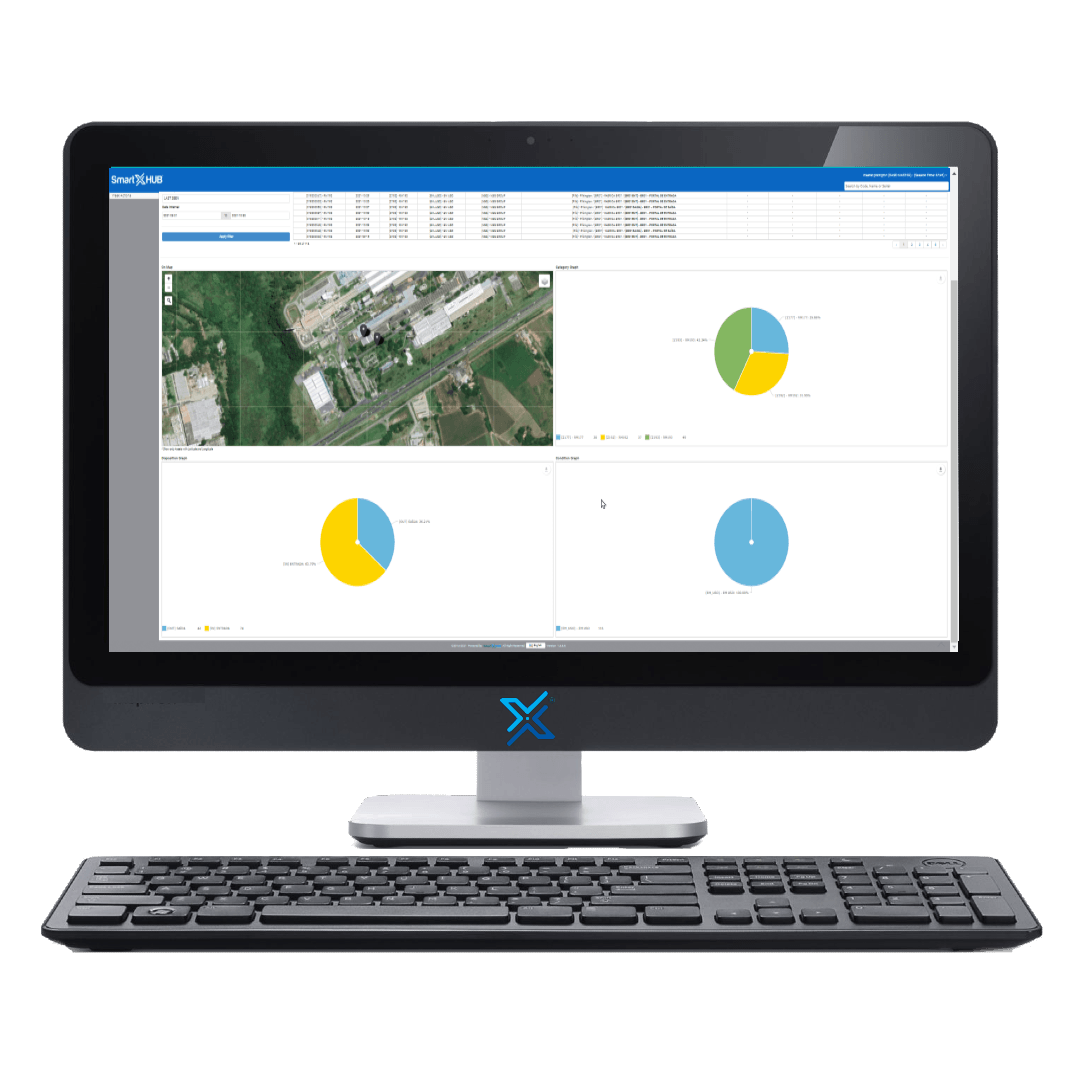

Transforming complex data into easy-to-understand visual information, the SmartX HUB solution provides powerful visual analytics to drive better operational decision making, identify areas for process improvement and apply predictive analytics to anticipate future asset needs.

The SmartX HUB object event repository provides highly scalable, object-level event processing throughout the supply chain. It enables discovery, tracking, reporting, and integration with business systems and enables business processes such as product tracking and authentication.

SmartX HUB IoT-RFID supports deployment at individual or local sites and enables organizations to integrate real-world and uniquely serialized data into their business software. It comes with preconfigured business processes such as RFID-enabled inbound and outbound logistics and returnable transport items processing.

5 Tips for Maximizing Oil & Gas Asset Utilization With RFID Effective asset utilization holds immense significance in the oil

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

IoT Ecosystem Empowerment: Advancing Workplace Safety and Efficiency with RTLS The Internet of Things (IoT) has arrived In the dynamic

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc