Manufacturing Automation Optimized With RFID

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

Track asset performance, execute maintenance and service, and maximize uptime with advanced technologies.

Deliver as promised with risk-resilient, reliable, and sustainable logistics operations.

A revolutionary convergence of personal and process safety that improve efficiency, safety and reliability.

Millions of returnable transport items (RTIs) such as containers, bins, pallets, racks and kegs move through the global supply chain, providing the most fundamental way in which parts, materials and finished goods reach their destination. However, the inability to effectively track these returnable and reusable assets creates considerable productivity, labor, cost and time inefficiencies. The end result is that companies spend more money purchasing additional logistics assets and hiring adequate labor to manage them.

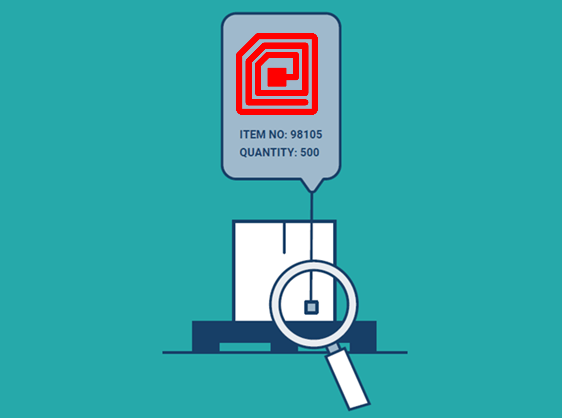

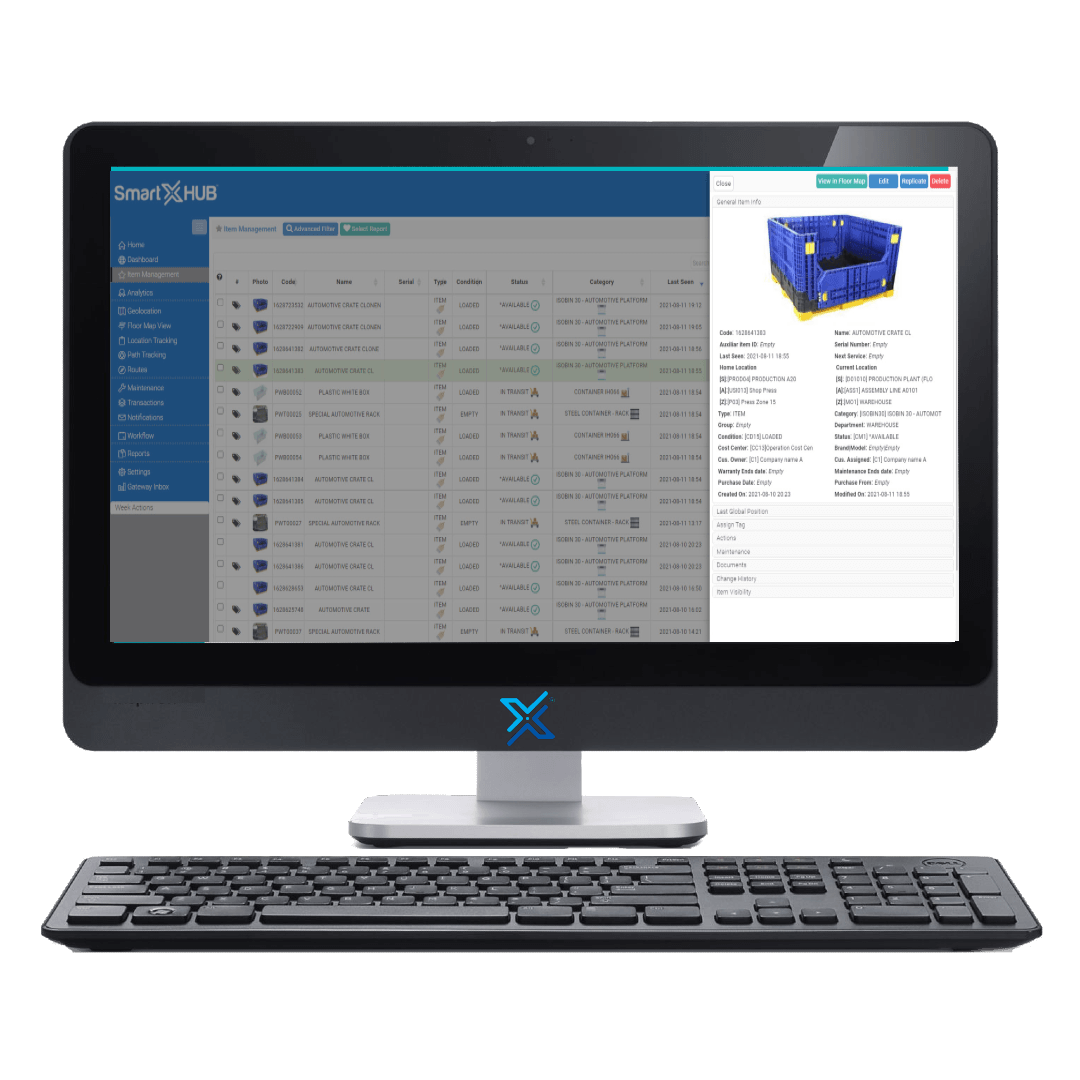

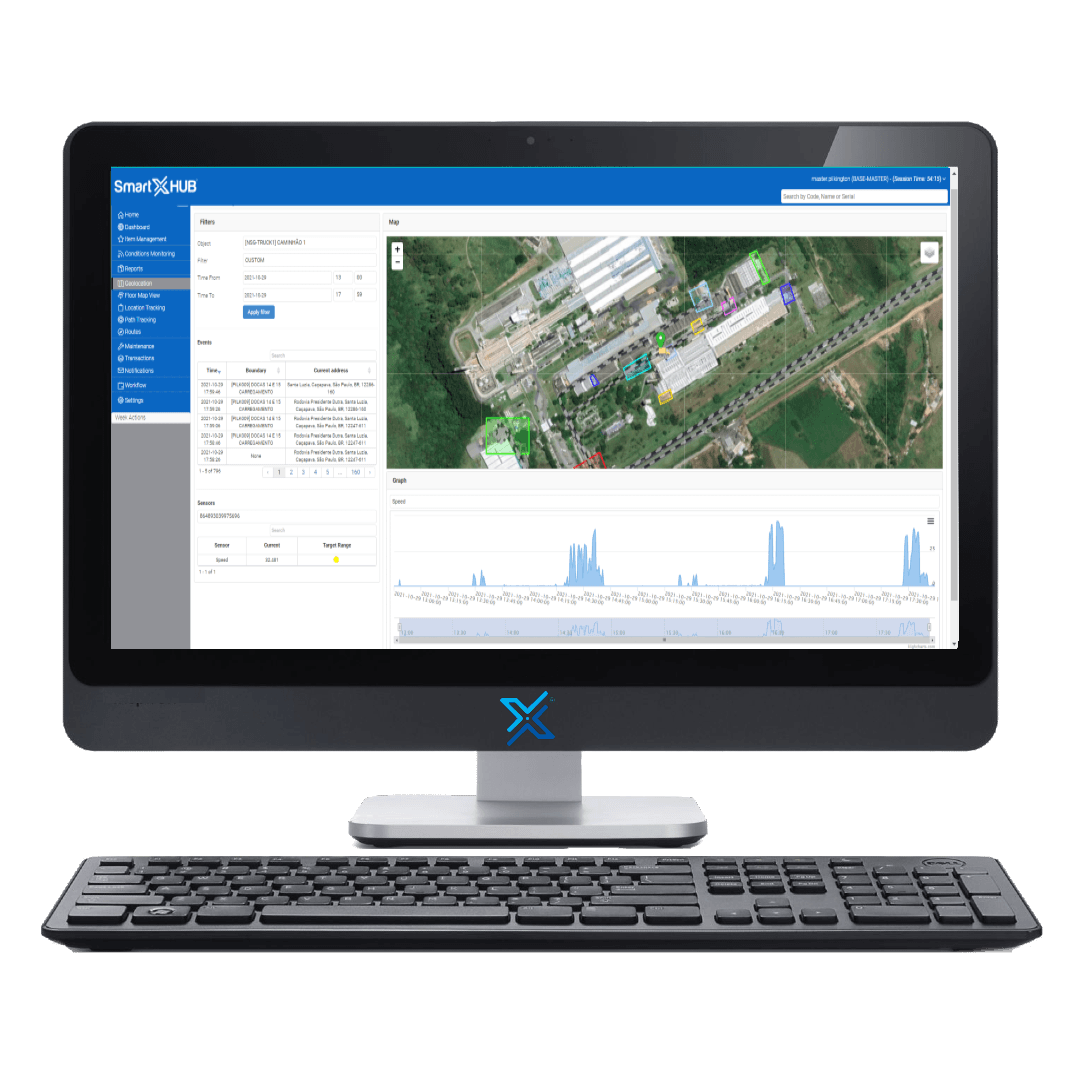

Each unique item can be identified and all its movements are registered. The in/out flow of goods can be controlled in bulk. RFID Asset Tracking enables you to know at any time the exact location of your RTIs and rental items. You can also evaluate the turnaround times of your logistics processes and thus improve your logistics flow. In addition, RFID Asset Management allows to trace not only the location and status of the assets, but also their history and use, giving you automatic updates on wear and life cycle. In this way, maintenance and replacements can be optimally scheduled.

Returnable containers are the primary method of transporting parts throughout modern supply chains. The use of returnable containers:

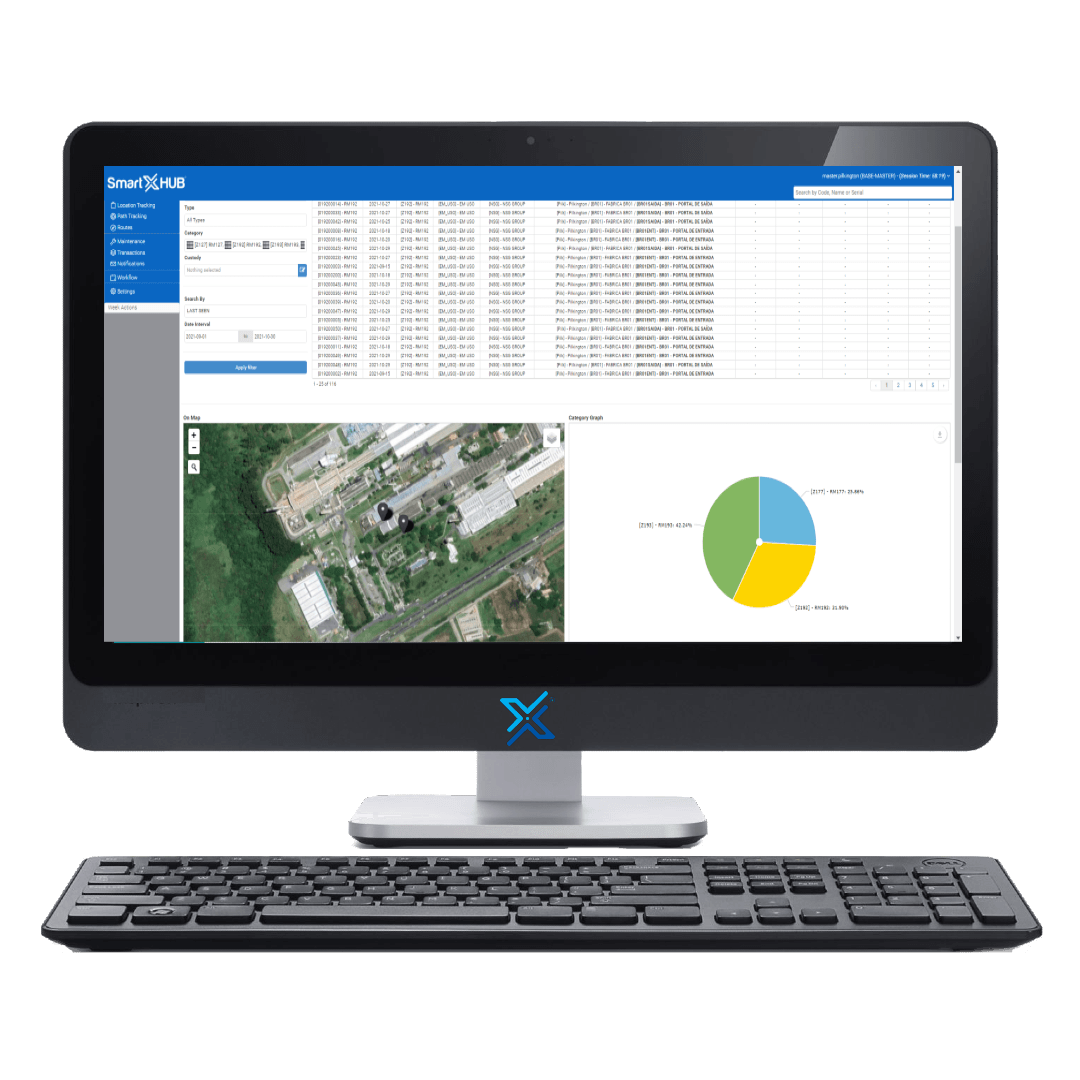

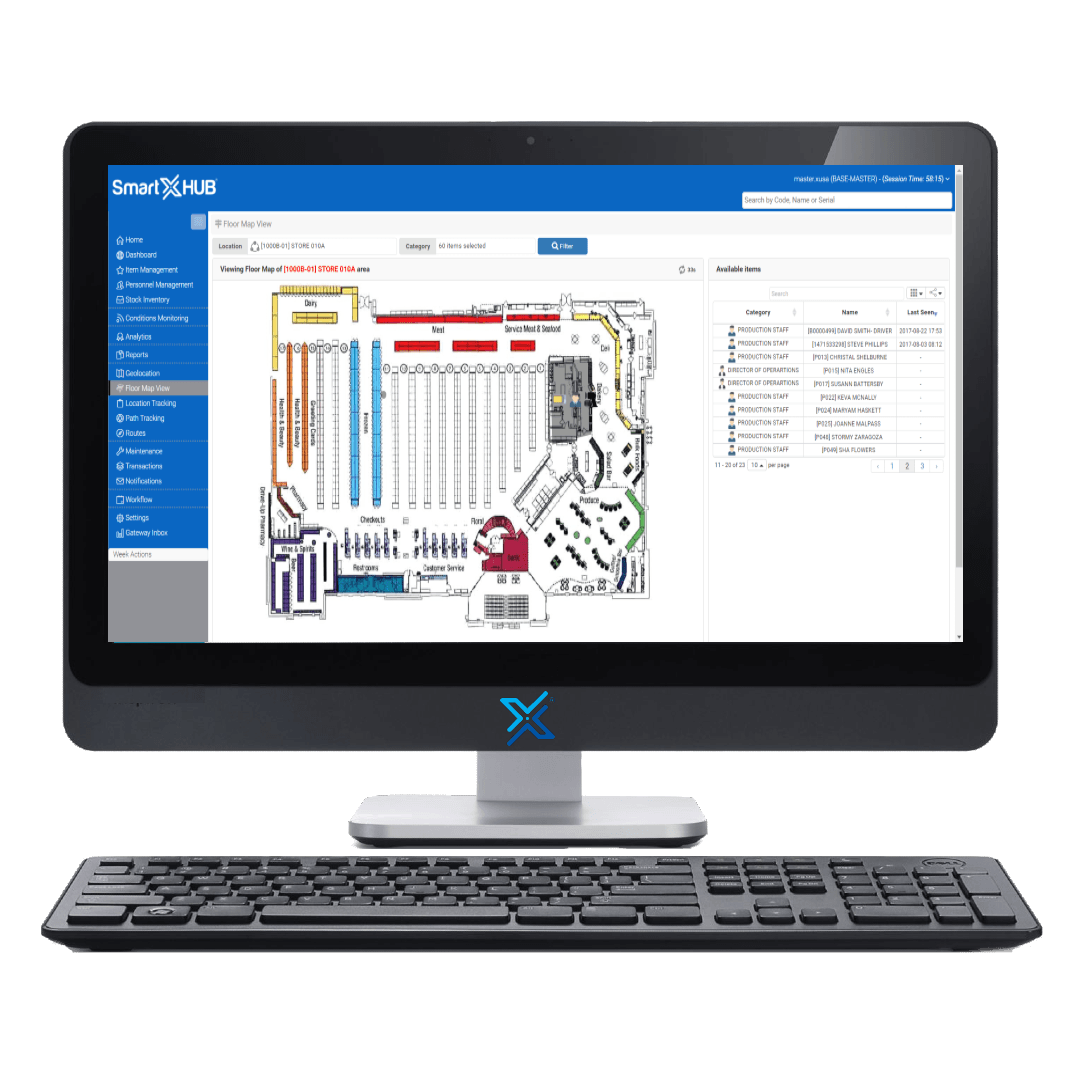

To track Returnable/Reusable Transport Items, we use radio frequency identification (RFID) or Beacon technology to help improve the management of assets. Our specially designed SmartX HUB system identifies individual pieces of equipment and tracks them across different sites to ensure they are in the place where they are needed.

The SmartX HUB solution dramatically raises asset efficiency, helping you to reduce purchases and optimize your rental program. Shrinkage control reduces lost, stolen or misplaced assets, with annual savings in the tens or hundreds of thousands of dollars.

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

What is RFID Asset Management? What is an RFID Asset Management System? It’s never been more cost-effective or so easy

How to Do Inspection Checklists Operator Rounds – The Digital Solution Market The market for digital inspection checklists has grown

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc