Reduce the time it takes to make important supply chain decisions by providing access to real-time information

Driving efficiencies throughout your supply chain and increasing the velocity of items through the supply chain from creation to the consumer is more than a business mandate today; it’s a matter of business survival. If your company doesn’t do it, your competition will.

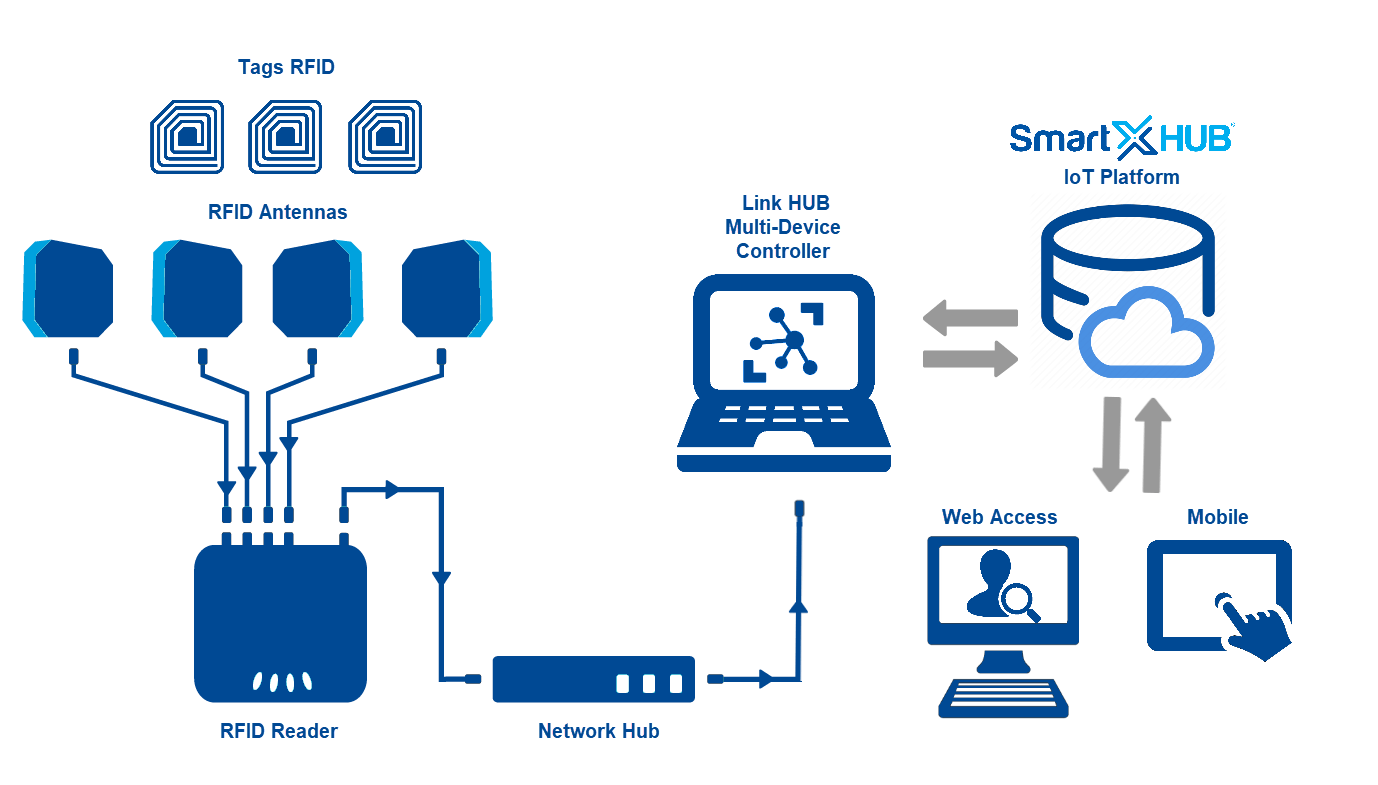

Radio Frequency Identification (RFID) is a true next-generation technology — ready, available, and being implemented today — transforming how companies manage and extract more business value from their supply chain operations.

Think of RFID as the next generation or an “enhanced” bar code. Like bar codes, it is an essential element of an enterprise mobility system, offering even greater access to information across your systems. With RFID, data capture takes a quantum leap forward, with much higher information capacity, non-contact information transmission, and always-on identification with limited or no human intervention. It takes capturing, moving, and managing information to the next level, and it allows companies to: