- Solutions

- Industries

- IoT Platform

asset management

security

- Resources

Resources

Products

Success Stories

RTLS Fundamentals

- Blog

- About

- En-US

Increase visibility and accuracy of the supply chain by providing real-time visibility to product flow with SmartX HUB RFID

There are three essential elements of an RFID system: tags, readers & antennas, and software with several options available for each component. Put, an RFID tag, like a bar code, stores information but can store considerably more information than bar codes. RFID tags exchange information with RFID fixed or mobile readers by radio signal or radio frequency (RF).

RFID technology is a natural fit for some applications offering incremental benefits and works in a complementary fashion or partners with bar codes in others. Although RFID tags and bar codes provide similar data capture functionality, there are several differences:

The tag, also known as the transponder, is at the heart of any RFID system. Two types of tags and their variants – active and passive – dominate the marketplace and are designed for specific applications. Active tags are battery-powered with onboard battery power sources, contain up to hundreds of kilobytes of memory, and can communicate data over longer ranges than passive tags. The tags are always on and always talking.

Active tags, mainly because of the built-in batteries, are far more expensive than passive tags. Active tags have been used for years and are typically used in long-range tracking applications to track high-value inventory.

Companies managing their supply chains primarily focus on passive UHF RFID tags. Because of their low cost and relatively long read ranges (up to 25 feet), these passive tags offer the best performance/value ratio across the supply chain.

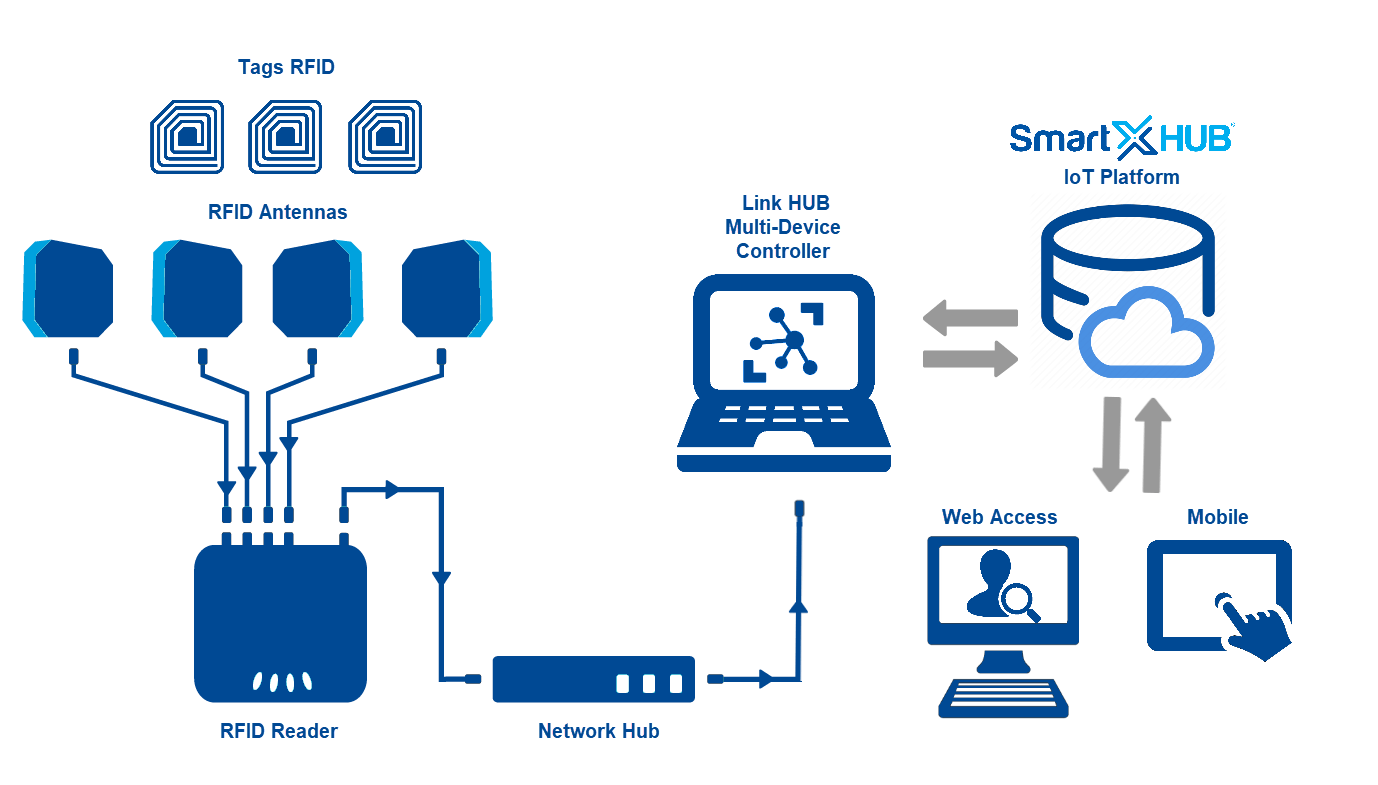

Passive tags communicate with readers leveraging backscatter technology and are “beam powered,” meaning they derive all of their operational power from the RF environment. The RFID reader generates a radio signal and broadcasts it via the connected antenna configured in a radio frequency (RF) field. A tag with an onboard antenna senses the radio signal and is energized, releasing its preprogrammed data and reflecting it to the reader via a modulated radio signal. The reader then decodes the reflected signal, aggregates the data, and passes the data to the host system. It all happens in an instant.

There are various types of readers, including mobile handheld devices, fixed-mounted readers, and vehicle-mounted readers — and form-factor variations. The environment, application, and a customer's supply chain requirements will determine the reader's choice. Choosing the best reader for the job will optimize performance, and it is not a one-tool-fits-all equation.

A reader that is right for a high-speed conveyor in a factory might not be the best tool for a chilly, 1.2 million square foot warehouse densely filled with RFID-tagged cartons and pallets.

A fixed reader would more likely be deployed for applications at the dock door, such as shipping/ receiving, or aligned along a conveyor belt as part of a work-in-process application.

Handheld RFID readers are typically used where the most flexibility is required. For example, exception processing, stock picking, price audits, or price changes are typical

applications for a handheld RFID reader. A handheld makes sense when it is more convenient to bring the reader to the item. Multi-protocol readers provide the capability to read Gen 2 tags. Advanced RFID readers will provide a firmware upgrade capability to Gen 2 and be dense-reader mode certified by EPCglobal.

Read ranges between tags and readers vary, and the user should look for readers that offer longer read ranges, higher yield quality, and flexible orientation. A reader offering a more industrial design is better prepared to face the challenges of actual-world use; in addition, look for readers that offer multi-reader modes, particularly dense reader modes, if the work environment is operating a large number of readers in a small area.

Readers are also offered as reader systems or packaged systems that deploy readers in multiple form factors, including portal systems, conveyor systems, and vehicle-mounted (e.g., forklift) readers. Packaged systems provide turnkey solutions which are designed for rapid enterprise deployment. Point product solution offerings are characteristic of early market technology. For RFID to reach broad, mainstream deployment, RFID solution vendors must offer packaged solutions to minimize the deployment complexity.

SmartX HUB is a next-generation RFID software platform for data collection.

It is a cloud-based asset tracking platform that leverages various AIDC technologies for data collection and analysis. The technologies include RFID, Barcodes, and more. SmartX HUB improves asset tracking and eliminates manual entry errors using RFID or Barcode technologies. It keeps track of your assets' complete life cycle (Receiving to Consumed / Disposed of), including scheduled maintenance or repair.

Link HUB is at the heart of the platform, an RFID Middleware software component that includes extensive reader management and enterprise-grade integration capabilities. In conjunction, there is a business suite of software applications to solve everyday business needs with vertical-based workflows, reporting, analytical and dashboard capabilities.

Now is the right time to invest in RFID. Choosing the right vendor for your enterprise operations is a critical business decision that will impact your bottom line, and the right decision will mean the difference between implementation success or failure.

SmartX HUB’s RFID expertise goes beyond products, and SmartX HUB understands the supply chain and has the deep vertical market expertise to ensure proper system design. Alongside our partners, we’ve focused on just that — helping companies implement solutions that enhance the efficiency of their supply chain.

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc