Manufacturing Automation Optimized With RFID

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information

Track asset performance, execute maintenance and service, and maximize uptime with advanced technologies.

Deliver as promised with risk-resilient, reliable, and sustainable logistics operations.

A revolutionary convergence of personal and process safety that improve efficiency, safety and reliability.

Our Client is an Automotive OEM, member of one of the world’s leading automotive alliances. Our Japanese Client, announced several initiatives as part of a new cooperation business model to enhance the competitiveness and profitability of the two other partner companies.

The Client invests in all vehicle segments and technologies, across all geographies, for the benefit of every customer, while increasing their respective competitiveness, sustainable profitability, and social and environmental responsibility.

Over the course of our Client’s project investigation into his returnable container tracking process, we have consistently found that most of the problems in today’s business processes relate to a lack of visibility – the inability to see what is happening across an entire returnable supply chain in near real time. It often became apparent very early that the OEM and their suppliers struggle with locating returnable containers and isolating issues when these containers are missing in the field.

A pool of Returnable Transport Items (RTIs) is often shared by different actors within the loop. However, the RTI pools can be quite ineffective if the pool handler has little visibility to RTI whereabouts. High capital costs are typical for shared pools as RTIs are not returned or they get lost or broken.

The Client has a complex manufacturing process with more than 50 thousand Returnable Containers and near 80 suppliers in the loop, posing significant operational, financial, and customer service implications for missing or inadequate shipping and receiving of these assets to suppliers.

The Client was looking for a special RFID tag that significantly eliminates errors under the new automated RFID system for RTIs packing preparation and shipment control.

In the Client’s supply chain, returnable containers are shipped on full pallets from an empties warehouse to the supplier, where they are filled with automotive parts and components that are then shipped to the manufacturer’s assembly line. Once the parts in a container have been consumed, empties are shipped on mixed pallets to the warehouse (often operated by a third-party logistics company) where they are sorted, treated, and refurbished. They are then reloaded on full pallets and are ready to ship out again to the supplier. In this system, there are several nodes where containers check in and out.

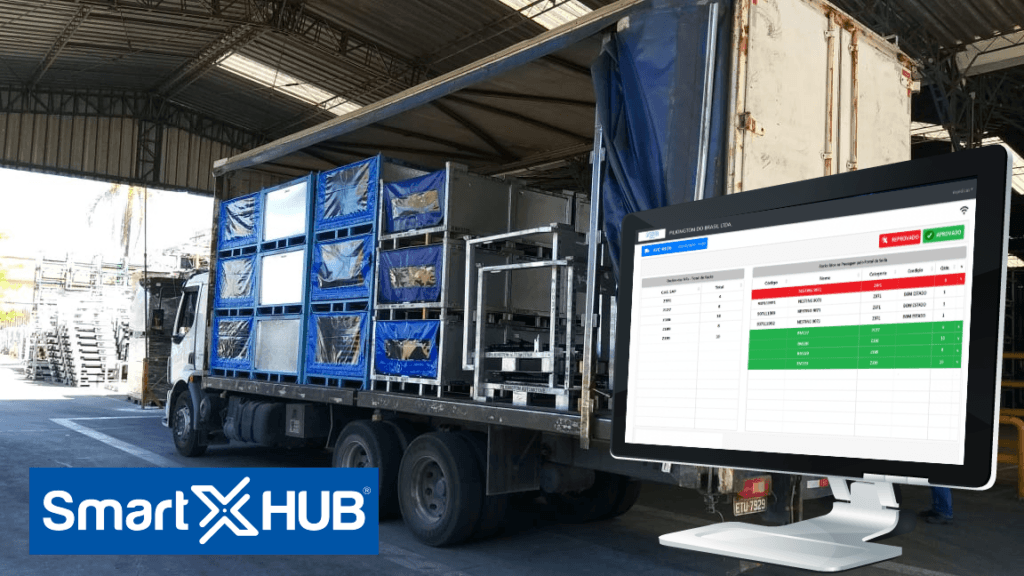

The SmartX HUB combines RFID technology with a robust cloud software platform that provides up-to-date, accurate inventory and supply chain information to help our Client with minimal time and labor.

The SmartX HUB processes for an RFID-enabled container management solution are fairly simple and straightforward. The Client places tags on all containers and plastic boxes. Reading the combination of container and insert tags allows the Client to determine which returnable container type is on hand. RFID readers are placed at the inbound and outbound dock doors of the empties warehouse, at the receiving and shipping docks of key suppliers, at sequencers’ and third-party logistics providers’ facilities if they are used, and certainly at the Client’s manufacturing facilities. As pallets of empty returnable containers leave a facility, tags are read by handheld and associated with a specific routing (shipment) so that the Client knows to which supplier the returnable containers are going and how many.

Once the truck is loaded, all transaction-relevant information is passed from the RFID Handheld to the asset management application, where the information is permanently stored and available for reporting and analysis. Naturally, a reconciliation between a returnable container order in a backend system and the asset management application or in the SmartX HUB RFID middleware can be automated to a point where the warehouse manager receives an instant alert when too many or too few containers are about to be shipped to the supplier.

Once the truck arrives at the supplier’s facility, RFID Handheld will perform a second scan of the empty returnable containers and allow for a second reconciliation of what has been shipped. If the same containers do not show up at the manufacturing site within a reasonable time, then it is the supplier’s responsibility to account for their whereabouts.

The visibility that the SmartX HUB system creates allows for shared ownership of returnables, which enables all participants in the automotive supply chain to handle each container to the best of their ability.

Improving audit, inventory, and shipping accuracy

The data management of returnable containers in the asset management application allows for the use of standard reports as well as for custom report development. It is possible to show the use of returnable containers per supplier, to report on suppliers that hold excessive returnable inventory and on those that take the most time to ship containers back. Gaining accurate inventory information provides better fiscal control and regulation compliance on capital assets.

Optimization in timing pickups and shipments

By measuring the time between scans, the OEM gains further insight into the transportation system, for example, why certain routes might take more time than others. This can lead to further optimization in timing pickups and shipments.

Real-time visibility for real-time decision making

Through the automation of data capture at each dock door in the system, it is also very interesting to draw conclusions on loads of trucks and to potentially use these insights for route and capacity planning in the future.

Reduce loss and lower costs

Ultimately, detailed knowledge of how returnable containers move through the SmartX HUB system allows a reliable assessment of how many returnable containers are needed and helps reduce inventory as well as avoid excessive spending for the next

program.

Explore our news to learn more about SmartX solutions

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information

IoT Ecosystem Empowerment: Advancing Workplace Safety and Efficiency with RTLS The Internet of Things (IoT) has arrived In the

California’s regulations for preventing heat-related illness in outdoor workers Introduction In situations involving high temperatures or extreme heat, it

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.