IoT Ecosystem Empowerment: Advancing Workplace Safety and Efficiency with RTLS

IoT Ecosystem Empowerment: Advancing Workplace Safety and Efficiency with RTLS The Internet of Things (IoT) has arrived In the dynamic

Track asset performance, execute maintenance and service, and maximize uptime with advanced technologies.

Deliver as promised with risk-resilient, reliable, and sustainable logistics operations.

A revolutionary convergence of personal and process safety that improve efficiency, safety and reliability.

Gain complete visibility into the location and report on the utilization of high-valued equipment that is critical to the success of your operations

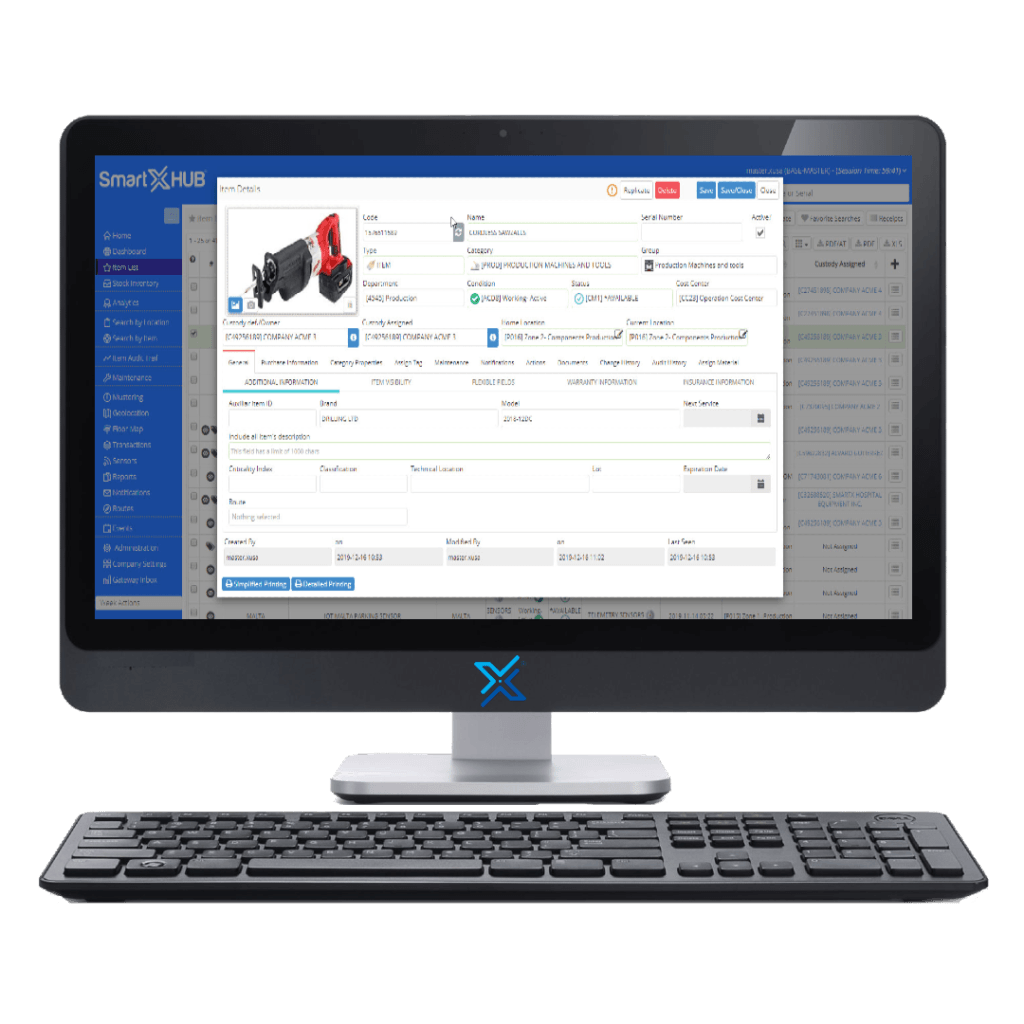

The technologies include RFID, iBeacons, Barcodes and more. SmartX HUB improves the asset tracking process and eliminates the manual entry errors using RFID or Barcode technologies. It keeps track of full life cycle (Receiving to Consumed / Disposed) of your assets including scheduled maintenance or repair.

Easily track your tools using any computer, smartphone or tablet. Just scan the QR code with your smartphone to view and update information on the go.

Improve operational decision making and material management workflow optimization through advanced visual analytics

Whether online or through our Mobile App, you and your team have on-demand access to asset information anytime, from anywhere, on the smartphones, tablets and computers you’re already using.

Audits, spot audits and inventory counts achieve (or approach) 100% accuracy and completeness. Regulatory compliance is as a result much easier to meet.

Audits and inventory counts are completed 50-90% faster than counts done with manual or bar code methods, saving both valuable personnel hours and substantial auditing cost.

The ability to virtually automate asset management practically

eliminates the need for staff to spend time inventorying assets and tracking down specific assets that are lost or misplaced, or require maintenance, repair or destroying. Some customers have reported as much as a 95 percent reduction in asset tracking time.

Asset ownership or responsibility is far easier to track and reconcile. This is an especially important benefit during office moves, facilities audits or data center expansion, consolidation situations or in production environments. It also adds to audit compliance ease.

Through greater asset visibility, and through the use of smart alarms, asset security is vastly enhanced.

Having the means to understand when planned maintenance should be scheduled, based on the usage of an asset, can help keep equipment running reliably and mitigates the risk of unplanned outages, which are a major source of delays.

Utilization reports generated by asset tracking solutions provide this means and allow you to adopt a preventative and predictive approach to service and maintenance as opposed to a break/fix service structure.

By retaining the last known location of the tagged assets, the RFID enabled solution provides inventory location information for assets across the facility. This perpetual inventory not only provides location data to help staff locate assets but creates an efficient method to account for equipment inventories.

Track rental equipment to ensure assets are returned on time and analyze utilization data to optimize the balance between capital and rental equipment—significantly lowering operational costs.

Monitor and analyze equipment utilization data across job sites against contract agreements and improve customer service through accurate billing.

Due dates, maintenance schedules, and owners. Use RFID or barcode scanning to instantly view all the information about specific leased equipment. Assign assets to specific customers or job sites for easier tracking

Contractors often build prefabricated elements (trusses, beams, etc.) off-site and then move those pieces to the construction yard when they’re needed. Using Smartx HUB, they can track prefab pieces starting from the time they’re created through the shipping process, and even after they’ve been delivered to the construction site. You can also get an alert when the piece is moved in the yard, which could indicate whether you’re on target for install.

Generate reports to keep up with equipment usage, depreciation and warranty. Location data can be used to optimize processes, meaning major implications for the company’s bottom line. For example, a contractor could use SmartX HUB to monitor time spent running each lift platform on a job site. If more equipment is rented than being used, they can update future rental agreements to cut costs.

With so many things happening on your construction site, you need a software that can keep track of your equipment, manage work orders, and keep your crew safe. Get real-time data on your assets and equipment from a centralized, always-connected, cloud-based solution.

IoT Ecosystem Empowerment: Advancing Workplace Safety and Efficiency with RTLS The Internet of Things (IoT) has arrived In the dynamic

IoT: The Internet of Things in Asset Management. The Internet of Things (IoT) has arrived The Internet of Things (IoT)

California’s regulations for preventing heat-related illness in outdoor workers Introduction In situations involving high temperatures or extreme heat, it is

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.