Manufacturing Automation Optimized With RFID

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

In the last decades, the market has undergone major transformations, but outdated practices are still observed in some companies. Analog processes such as using printed forms and clipboards or even digital practices without integrations such as using spreadsheets or cameras make it difficult to access data and hinder decision-making.

Migrating from this level to a digital environment is a mandatory trend for companies that want to stay in the market. Therefore, keeping up with technological innovations is no longer just a matter of improvement, but of survival to achieve a healthy and competitive business model.

The Internet of Things (IoT) in asset management brings significant changes to maintenance processes. By using sensors and programs, IoT technology enables the automatic and intelligent collection of data on the behavior and functioning of machines and equipment. This data can be used to prevent failures, optimize equipment life, and improve energy consumption.

By integrating IoT technology with management platforms and applications, remote and real-time monitoring of data becomes possible. This allows for more agile and efficient decision-making and helps companies transition from analog to digital processes. In short, IoT in asset management transforms maintenance from a reactive to a proactive process, improving efficiency and reducing costs.

Automation of processes is undoubtedly the significant improvement that comes with the arrival of IoT. Information previously collected, transmitted, and stored on paper can now be automatically generated and stored on servers for easy access by anyone who needs this data. Consequently, we have time savings and an increase in the effectiveness of these processes.

As an example, let's think of a hotel kitchen. One refrigeration equipment malfunctioned due to a blockage caused by excess ice. On-site, the technician had to empty the equipment, clean it, disassemble it, and only start testing. After all this process, he discovered that the problem was a burnt resistor, and he finally replaced it to reassemble the equipment.

From the description, we can understand how expensive, time-consuming, and highly unproductive this procedure is. Now let's imagine the same case with the application of IoT. Imagine that the maintenance manager had access to data from a sensor capable of checking the temperature and consumption of the equipment. When it shows any change in the standard operating patterns, a technician could be notified before the blockage even happens.

In addition to optimizing the execution of processes, automation allows you to verify the urgency of the service. The failure described above, for example, is not so severe and allows for corrective action planning. However, temperature elevation is a critical indicator and demands immediate intervention.

Maintenance is increasingly moving away from the operational to focus on strategy. Fixing broken equipment is no longer the only focus. The goal is to achieve better results by increasing performance while reducing costs. For this, IoT is an excellent first step, but it is not the complete solution. For it to be effective, it is necessary to connect data to develop action plans using intelligent analysis.

This can be achieved by cross-referencing sensor information with service data and equipment history. Only then is it possible to have accuracy in the analysis to decide on the best services for each asset?

The monitoring of sensors is just one part of the whole process. To make it work fully and achieve maximum efficiency, it is necessary to pay attention to the entire process, from generating alerts to planning, monitoring, and validating the service.

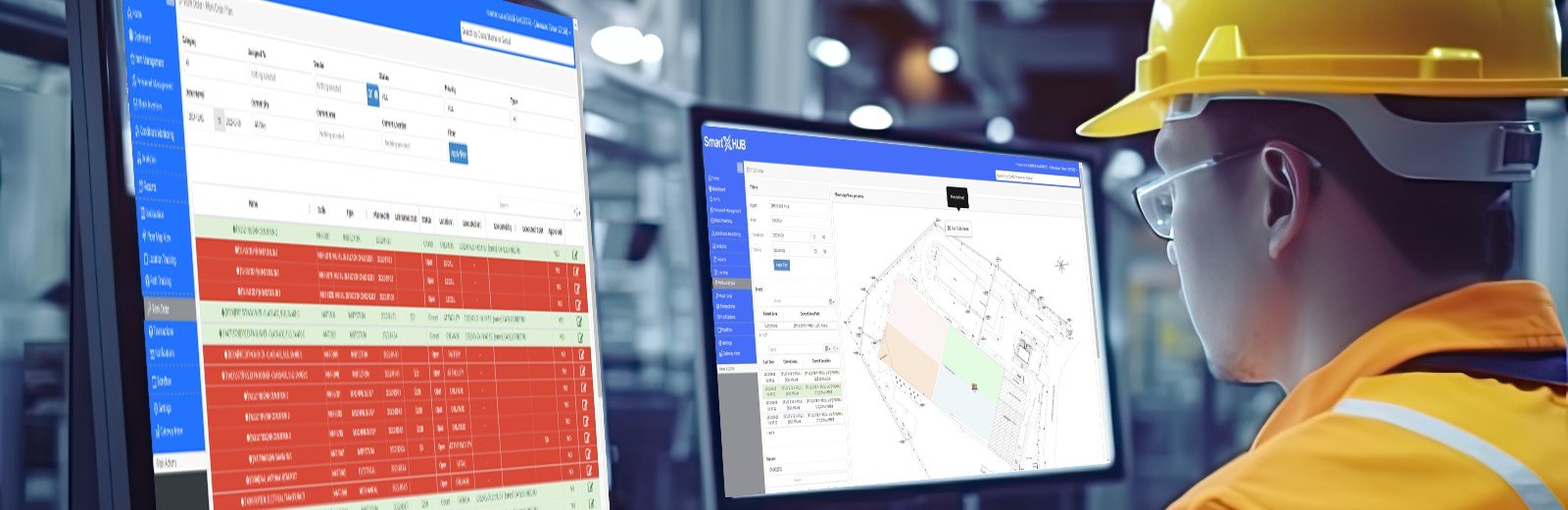

This is the proposal for the SmartX HUB Insights solution. With our IoT platform, it is possible to monitor the health of your critical assets in real-time, obtaining data such as vibration, temperature, pressure, humidity, flow, and geopositioning, among others. Then, with the possibility of monitoring behaviors and diagnosing events with intelligence, it is possible to predict what will happen to your assets and focus on actions that need to be taken soon for maximum availability. All of this with platform integration, available in WEB and MOBILE environments.

Smartx HUB is an IoT platform that can help in maintenance by providing real-time data on the health and performance of equipment and predictive analytics to identify potential issues before they become critical. The platform can integrate with various sensors to collect data on parameters such as temperature, pressure, vibration, and humidity.

By analyzing this data using machine learning algorithms, Smartx HUB can identify patterns and anomalies that may indicate a potential issue. It can also generate alerts and notifications when a parameter goes outside a set threshold, allowing maintenance teams to take proactive action before a failure occurs.

Smartx HUB also provides a dashboard that displays key performance indicators (KPIs) such as uptime, downtime, and mean time between failures (MTBF). This allows maintenance teams to monitor their equipment's overall health and identify improvement areas.

Overall, Smartx HUB can help maintenance teams improve their operations' efficiency and effectiveness, reduce downtime, and optimize their maintenance schedules.

SmartX HUB’s global presence and deep industry and business transformation expertise have proven that the methodologies and experience gained from thousands of worldwide engagements help clients achieve actual business results and innovation quickly and cost-effectively.

To get more information on how we can help you overcome the challenges to your construction business or to check out a free demo, contact us.

Contact us at the SmartX office nearest to you or submit a business inquiry online.

Let us know how we can help you solve your business challenges!

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

IoT Ecosystem Empowerment: Advancing Workplace Safety and Efficiency with RTLS The Internet of Things (IoT) has arrived In the dynamic

California’s regulations for preventing heat-related illness in outdoor workers Introduction In situations involving high temperatures or extreme heat, it is

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc