Cosmetic Care: Smart Monitoring Solutions for L’Oréal’s Warehouse Excellence

L’Oréal’s Warehouse Temperature Monitoring Success. L’Oréal Brazil, a leading cosmetic company renowned for its innovation and commitment to delivering high-quality

Don’t overlook the small things in your quest for efficiency. Solving the pain in these processes will lead to bigger and better transformation down the road. We can help!

Track asset locations in one place. SmartX HUB can track and manage all asset information, including contracts and expirations.

Consolidate all IT and non-IT asset data in one place. SmartX HUB is brand agnostic and can track and manage all asset information, including contracts and expirations.

Centralize your data. SmartX HUB can help with inventory locations, cycle counts, stock levels, and more to keep your ops running smoothly.

IT time is spent deploying, managing, integrating, maintaining, and upgrading without a consolidated asset management platform—and all the related disruption and expense. With SmartX HUB, operational costs are significantly reduced, and IT can focus on activities that directly contribute to business growth.

With SmartX HUB, employees are no longer bogged down navigating inefficient and disjointed processes and the sneaky manual tasks that steal time. The time that should be spent helping the company grow.

Because SmartX HUB extracts data from a single, centralized data repository, errors—which disparate systems are prone to—are eliminated. And, with a holistic view of inventory and assets, you’ve got the critical business intelligence needed to manage the business effectively.

While using RFID tags to maintain a database of your assets, tools, and equipment can deliver a more durable option than barcoding, its main advantages are automation and speed. Using an RFID tracking method helps automate the assets and equipment check-in and check-out process and can reduce the number of personnel you have dedicated to keeping track of inventory.

Also, an advanced RFID tracking application, such as SmartX HUB, gives you a flexible self-service asset check-out that can improve worksite efficiency and give you a one-stop shop for your inventory needs.

RFID Asset tracking is becoming increasingly popular as RFID tag prices drop and reliability increases. The tags have several advantages over bar codes when it comes to asset tracking:

-RFID tags do not need a line of sight to be placed inside tools or assets.

-Multiple RFID tags can be read at the same time to speed processing

-The tags are rugged and generally last longer than bar code labels, making them perfect for construction inventory management

However, we also believe that there is a need for both RFID tags and bar code labels, as there are some disadvantages to RFID asset tracking:

-RFID tags are often more expensive than bar code labels, so they’re not always practical for inexpensive items

-They are challenging to read through metal and in liquid environments without unique tags

We offer the best of both worlds. SmartX HUB’s asset tracking system provides mobile computers that offer RFID capability and can also read bar codes for ultimate flexibility.

SmartX HUB® platform helps companies be more efficient, accurate, and connected by secure cloud computing.

Built on a modern microservices architecture, SmartX HUB drives visibility around how we track and manage various assets, inventories, and items.

SmartX HUB is specifically designed to connect the data companies need to impact their daily business operations.

The following video illustrates this shared, increasing the accuracy and efficiency of the asset count process.

The read-write capability of SmartX HUB RFID technology enables the automation of record-keeping for asset maintenance. This, in turn, ensures the highly accurate and complete maintenance records required to best adhere to maintenance schedules and optimize an asset’s performance.

As a technician completes service, critical maintenance data can be associated to the asset tag — such as service date and time, technician, service performed, and next inspection date. An asset’s complete history is always available to the technician with a quick read of the asset’s RFID tag. And in addition, the information can also be sent automatically to the SmartX HUB EAM module, ensuring the timely scheduling of future maintenance required to maximize equipment uptime.

SmartX HUB includes pre-configured reports that allow organizations to more effectively manage their asset inventory and utilization. The SmartX HUB software application includes several reports that are based on information that is, by default, refreshed hourly in the solution.

Every business has a unique inventory situation requiring a carefully customized tracking solution. This solution is achieved by a thorough evaluation of the different inventory types in your arsenal and an evaluation of which type of tracking label is best suited for optimal workflow, safety, and budgetary concerns.

Here are some of the clearest benefits of SmartX HUB RFID Maintenance management at a job site:

SmartX HUB Tool tracking software can send notifications and alerts to an inventory manager’s mobile device when stock levels are running low. Your central asset register can also provide the inventory manager with the supplier’s details to efficiently replenish stock.

Using a centralized tool tracking solution that integrates with your existing systems enables you to create and build a fixed register of all the assets tied to your business. That allows you and your asset management team to access real-time data on demand, whether it’s maintenance plans, current location, utilization rates, or depreciation value. That register is stored in the cloud so you can access it anytime and from anywhere while removing the need for time-consuming and error-prone spreadsheets.

Tool tracking software can help you improve your asset maintenance accuracy and efficiency by providing real-time insights about usage. Asset utilization metrics such as engine hours and downtime can help you decide when to perform preventive maintenance and routine fixes to keep your assets running efficiently. You can also set up alerts for when parts need replacing to avoid costly breakdowns.

Gain item-level data about every asset to ensure essential tools and equipment don't get lost, misplaced, or stolen. You can reduce overall inventory levels by keeping up-to-date on your tools' whereabouts while ensuring adequate supplies across all locations.

SmartX HUB Solution helps you obtain a more efficient workflow by improving your control over your project, enhancing safety on your Jobsite, reducing equipment downtime, minimizing safety hazards, increasing equipment life expectancy, and reducing repair costs. It provides you with the necessary means to stay on schedule, stay on budget and work consistently to keep your overall project on the right track.

A traditional inventory management system typically manages tool inventory with bar codes and requires a tool crib attendant to handle tool issues and returns. With the introduction of technologies like radio frequency identification (RFID), new efficiencies in tool tracking solutions have been developed.

These solutions, like SmartX HUB's RFID, are fully automated, enabling workers to quickly get and return the tools they require without a tool attendant while keeping the employee accountable.

SmartX HUB's RFID tool tracking also provides real-time visibility with a completely automated self-service kiosk and inventory management tool.

By automating your processes with SmartX HUB RFID-IoT technology, you can cut daily operational costs by significantly reducing labor and error costs through process automation. SmartX HUB offers a scalable, customizable and straightforward platform, easily fitting into your unique business process. SmartX HUB runs on any web browser and any Windows, iOS, or Android device to make it even easier.

SmartX HUB's global presence, coupled with its deep industry and business transformation expertise, has proven that the methodologies and experience gained from thousands of worldwide engagements help clients achieve accurate business results and innovation quickly and cost-effectively.

Contact us to get more information on how we can help you overcome the challenges to your business or to check out a free demo.

Contact us at the SmartX office nearest to you or submit a business inquiry online.

Let us know how we can help you solve your business challenges!

L’Oréal’s Warehouse Temperature Monitoring Success. L’Oréal Brazil, a leading cosmetic company renowned for its innovation and commitment to delivering high-quality

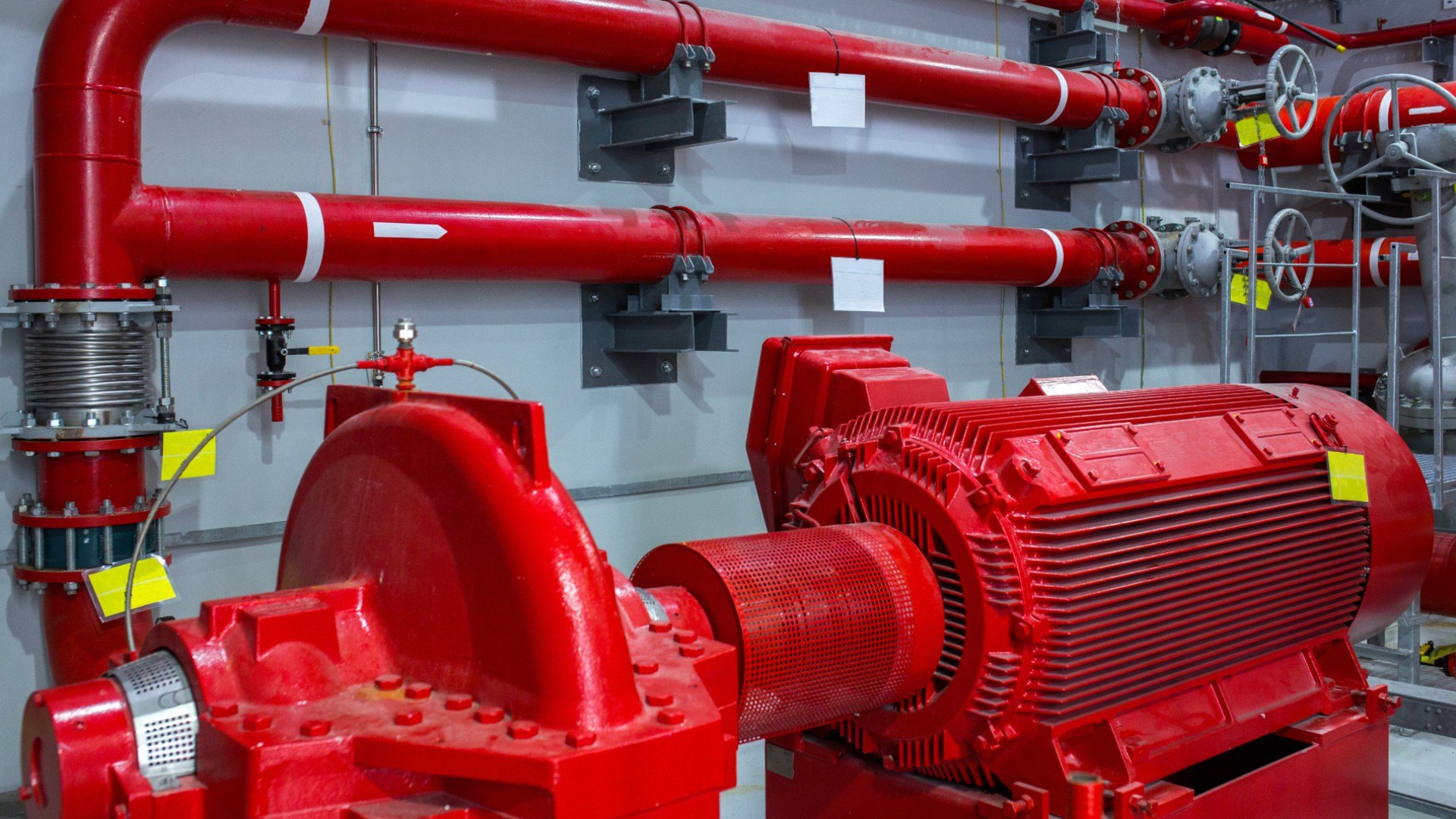

5 Tips for Maximizing Oil & Gas Asset Utilization With RFID Effective asset utilization holds immense significance in the oil

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc