Manufacturing Automation Optimized With RFID

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

Track asset performance, execute maintenance and service, and maximize uptime with advanced technologies.

Deliver as promised with risk-resilient, reliable, and sustainable logistics operations.

A revolutionary convergence of personal and process safety that improve efficiency, safety and reliability.

Connected safety solutions encompass a network of cloud-connected devices, including area monitors and personal wearable devices. When integrated with an online dashboard, these devices offer comprehensive insight into the safety of both facilities and personnel.

The data streamed by these devices empowers managers with robust reporting capabilities at their fingertips. Additionally, it monitors the devices' operational status, ensuring they are charged, powered on, and actively used throughout a shift. This valuable information can be accessed from anywhere in real-time, eliminating the need to wait until the devices are docked to receive the data.

Furthermore, through data analysis, these connected safety solutions can identify and predict potential hazards, enabling proactive corrective measures to be taken before they escalate into incidents.

To best illustrate the numerous advantages of connected safety solutions, it's helpful to provide practical examples from the construction industry. Below are common risks encountered in construction, along with insights into how connected safety solutions can effectively mitigate these risks.

A common scenario in the construction industry involves working at elevated heights, and Falls From Height stands as a leading cause of occupational fatalities, also ranking as the primary cause of nonfatal preventable injuries according to the NSC. Within a connected safety framework, wearable devices are equipped with sensors and functionalities designed to automatically detect falls, or prolonged inactivity – any of which could signal that a worker requires assistance. Picture workers perched high above the ground on a towering structure, potentially injured and unable to communicate for help. A connected safety solution eradicates this vulnerability. Moreover, this technology proves invaluable for lone workers who might be scattered across a vast construction site, lacking frequent contact with others and often beyond the line of sight of their colleagues.

With these connected devices, workers can trigger SOS alerts, connecting them instantly to safety monitoring personnel in the event of an incident requiring assistance.

The real-time awareness of workers ensures that safety team leaders can rest assured, knowing that continuous, uninterrupted monitoring is in place for each team, even in the face of the worst-case scenarios.

Beyond toxic gases, the release of flammable gases from storage tanks during activities like demolition work poses a significant risk of fire and explosions. In the unfortunate event of an emergency, connected safety solutions play a pivotal role in streamlining reactive responses, simplifying evacuation procedures for a quicker and more efficient response.

When hazardous gas levels suddenly spike, safety personnel are promptly alerted, facilitating the swift evacuation of workers from affected areas while ensuring that no one is inadvertently left behind. Throughout the evacuation process, team leaders can actively track the real-time locations of all individuals wearing connected safety devices, guaranteeing their safe arrival at designated muster points. Given that worker locations are readily accessible on the dashboard, immediate assistance can be dispatched to anyone who hasn't successfully evacuated. This capability saves crucial seconds and can make the pivotal difference between successful rescue and unfortunate recovery.

Furthermore, thanks to the multifaceted data captured by connected devices, rescue teams can assess the appropriate response to various incidents, whether it involves a fall, lack of movement, or exposure to elevated gas levels, potentially necessitating the use of full breathing apparatus.

Many of us can relate to moments of being in 'autopilot' mode. This inclination, along with worker complacency stemming from habitual actions, has been pinpointed as a significant contributor to workplace injuries.

Engaging in repetitive actions over time, especially if they've never resulted in negative consequences, can foster a false sense of safety, even when these actions are inherently risky. Given that 5% of accidents are attributed to unsafe behaviors rather than hazardous conditions, this issue represents a substantial challenge across various industries, particularly those involving heavy machinery and the potential for collisions, such as construction sites. Workers may carry out tasks automatically, without a true consideration of their approach or whether there might be a safer way to perform them. This lack of awareness can be due to a limited understanding of the associated risks or inadequate training in assuming responsibility for their own safety.

One effective strategy to combat complacency is to provide workers with digital tools that promote awareness of their actions and the potential consequences, encouraging them to correct their behavior. Connected technology plays a pivotal role in this regard. When management conducts an analysis of behaviors and incidents, examining collected data to form a comprehensive overview of what is transpiring and who is at risk, it can drive substantial improvements in workforce safety. By addressing the issue from both the perspective of worker awareness and data analysis, meaningful enhancements in safety within the workforce can be achieved.

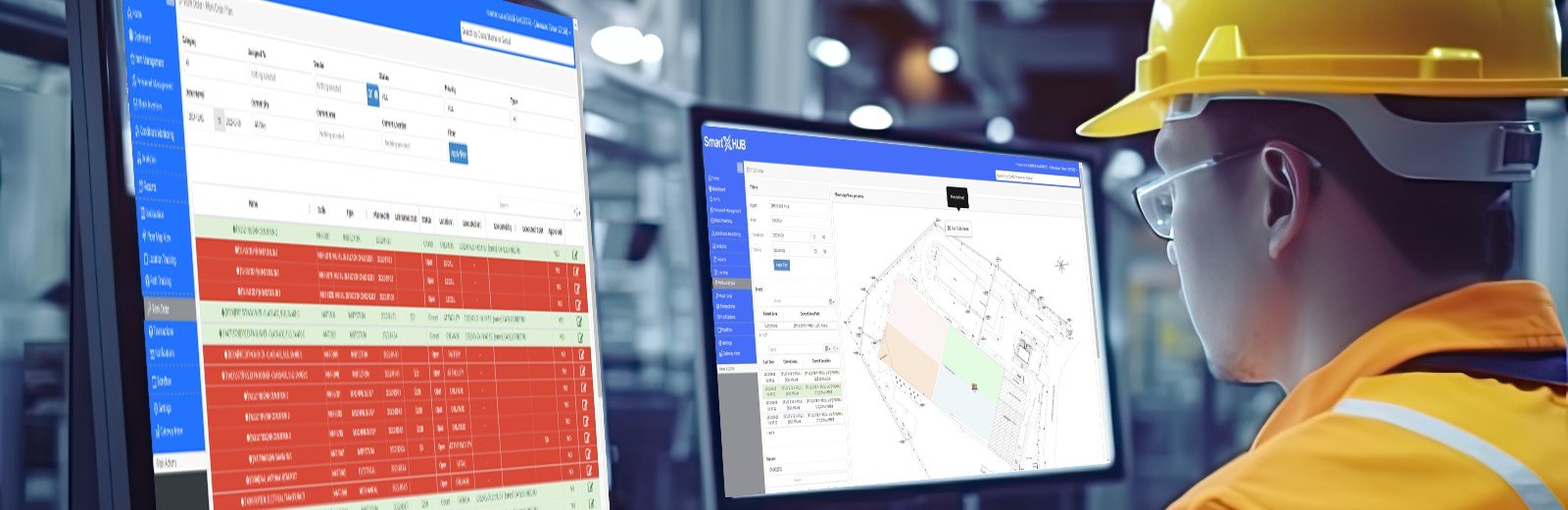

SmartX HUB stands at the forefront of technological innovation in the industrial workforce, harnessing the power of IoT (Internet of Things) to drive positive change. Through a combination of connected safety devices and predictive analytics, SmartX HUB empowers companies to strive for the goal of zero safety incidents while enhancing operational performance.

SmartX HUB offers a range of solutions, including wearable devices, personal and area attendance, cloud-connected software, and data analytics, to address the rigorous safety demands faced by organizations. These solutions are designed to not only meet safety challenges head-on but also boost overall productivity. With a global presence spanning over 20 countries, SmartX HUB is equipped with cellular connectivity, effectively serving as a lifeline for individuals.

For further information, please visit smartxhub.com, and stay connected with SmartX HUB on social media platforms including Facebook, Twitter, LinkedIn, and Instagram.

Contact us at the SmartX office nearest to you or submit a business inquiry online.

Let us know how we can help you solve your business challenges!

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

IoT Ecosystem Empowerment: Advancing Workplace Safety and Efficiency with RTLS The Internet of Things (IoT) has arrived In the dynamic

California’s regulations for preventing heat-related illness in outdoor workers Introduction In situations involving high temperatures or extreme heat, it is

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc