Enhance inventory management.

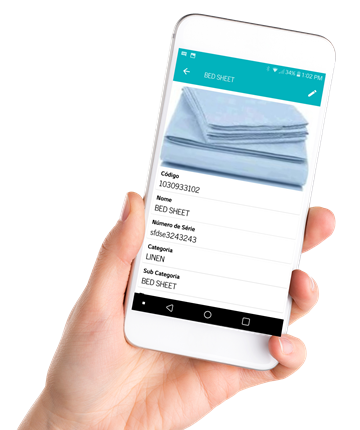

For institutions that require a constant flow of clean linen, uniforms, work wear, medical garments, or janitorial supplies, SmartX’ s radio frequency identification (RFID) tags enable automated systems to track large volumes of individual items faster and more accurately.

SmartX Radio frequency cloud platform enable uniform companies, commercial launderers, and medical facilities to automatically track clothing, linens, rags and other assets, resulting in more accurate, efficient inventory management and accounting practices.

Streamline commercial laundry systems.

SmartX Platform allow commercial laundry logistics that are optimized via RFID technology, to increase processing speed and accuracy through each cycle of cleaning and use.

Our Platform enable real-time tracking of tagged items, from retrieval of soiled linens, through sorting, laundry or dry cleaning, pressing, folding, packaging and distribution.

With SmartX Uniform management companies can use our solution from us to more accurately control asset lifecycles, increasing garment productivity by 20 percent, reducing through put by 15 percent, and also decreasing stock requirements per customer an average of 12 percent.

Commercial launderers and dry cleaners can employ our RFID Platform to ensure accurate item counts and documentation, enabling automatic billing and accurate inventory control.

Improve infection control processing.

The healthcare industry can also realize the benefits of better documentation and improved inventory control for bed linens, towels, napkins and tablecloths. In addition, RFID technology is helping hospitals achieve significant reductions in linen theft and depreciation.

In addition to asset management and inventory control benefits, medical facilities are implementing RFID devices to improve infection control processes.

Health care facilities can better ensure patient and staff safety by effectively tracking reusable assets, and verifying cleaning and sterilization procedures. SmartX tags designed for industrial laundry applications perform exceptionally well in hospital and clinic environments, despite exposure to fluids, chemicals and sterilizing heat.