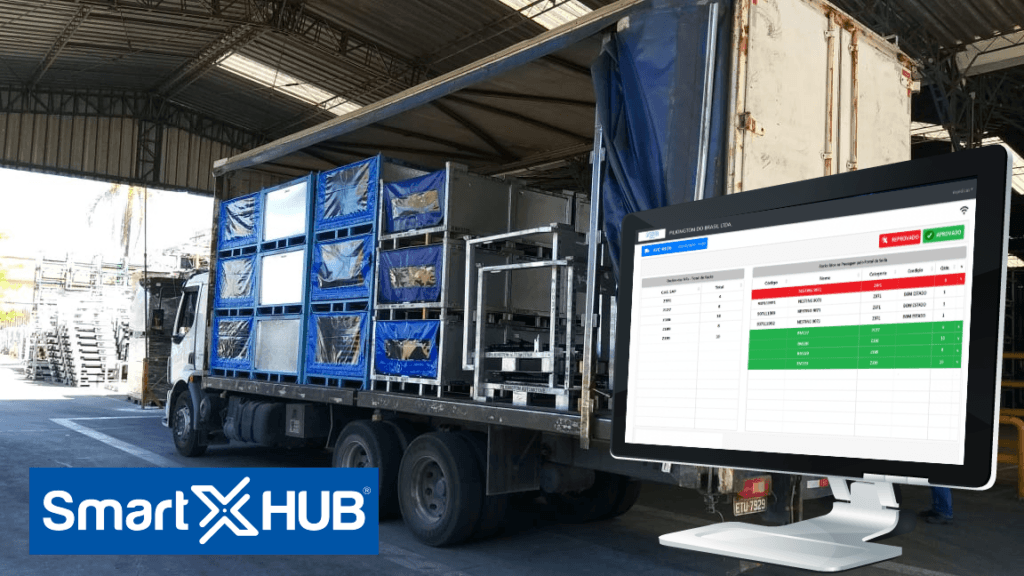

SmartX HUB’s RAIN RFID solution prevents costly shipping errors

The visibility that the SmartX HUB system creates allows for shared ownership of returnables, which enables all participants in the automotive supply chain to handle each container to the best of their ability.

Improving audit, inventory and shipping accuracy

The data management of returnable containers in the asset management application allows for the use of standard reports as well as for custom report development. It is possible to show the use of returnable containers per supplier, to report on suppliers that hold excessive returnable inventory and on those that take the most time to ship containers back. Gaining accurate inventory information provides better fiscal control and regulation compliance on capital assets.

Optimization in timing pickups and shipments

By measuring the time between scans, the Client gains further insight into the transportation system, for example, why certain routes might take more time than others. With real-time information and tracking, Client was able to accurately manage and deploy assets.

Real-time visibility for real-time decision making Inbound and outbound items are automatically counted as they pass through dock doors. As assets move in and out of the warehouse, the system is updated in real-time without the need for manual scanning.

Reduce loss and lower costs

Ultimately, detailed knowledge of how returnable containers move through the SmartX HUB system allows a reliable assessment of how many returnable containers are needed and helps reduce inventory as well as avoid excessive spending for the next

program.