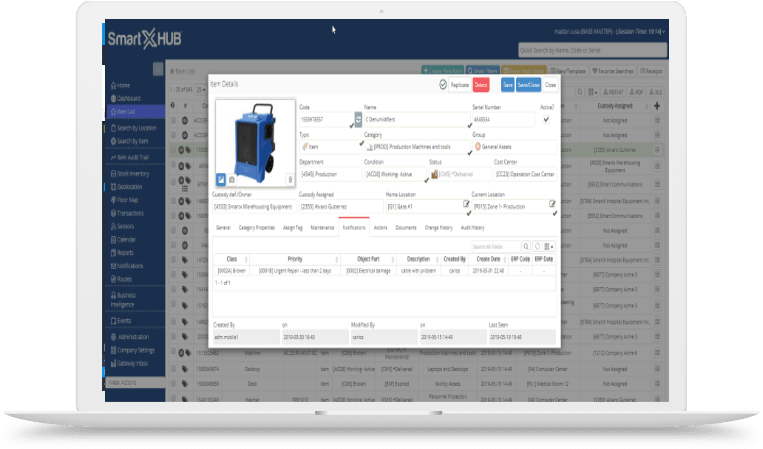

The traditional methods like paper-based tracking used for tracking materials have lots of problems. The RFID technology helps in overcoming these problems that traditional methods have. There are multiple components in an RFID based tracking system.

A basic RFID based tracking system contains tags and readers. The tags are attached to the physical materials to be tracked, and the reader communicates the data from the tags. The tags become active only in the presence of the readers. However, active tags are also available, which are active all the time, because they have a built-in power supply. The active is little costly but they also have better readability than the passive tags as they are active all the times.

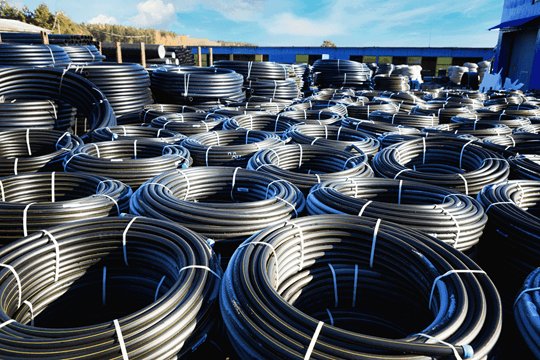

Using radio frequency, the RFID reader communicates data to and from the RFID tags. The data is then shared with a software system, where it is processed and necessary business decisions can be taken. The RFID tags are placed on the stack of the metal roof panels. The RFID tracking system gives the accurate counts of the panels in the stack. The system is a great way to check the inventory and monitor quantities.

We can also track the location of the panels in a warehouse storage space. In case of multiple storage sites, accessing the materials becomes easy as typing in the information about the item reveal the exact location of the item because it was scanned and keyed in. A different approach will be using different readers attached to different locations.

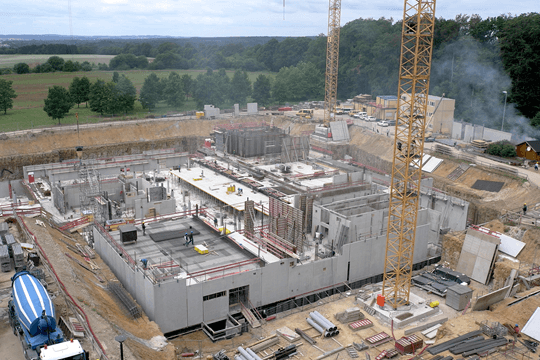

Systematic analysis of the inventory would also reveal the requirement of the inventory before the construction project starts. The required items can be pre-ordered so the project can start on time, and not be interrupted by having to order the materials in the middle of the project.