Manufacturing Automation Optimized With RFID

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

Track asset performance, execute maintenance and service, and maximize uptime with advanced technologies.

Deliver as promised with risk-resilient, reliable, and sustainable logistics operations.

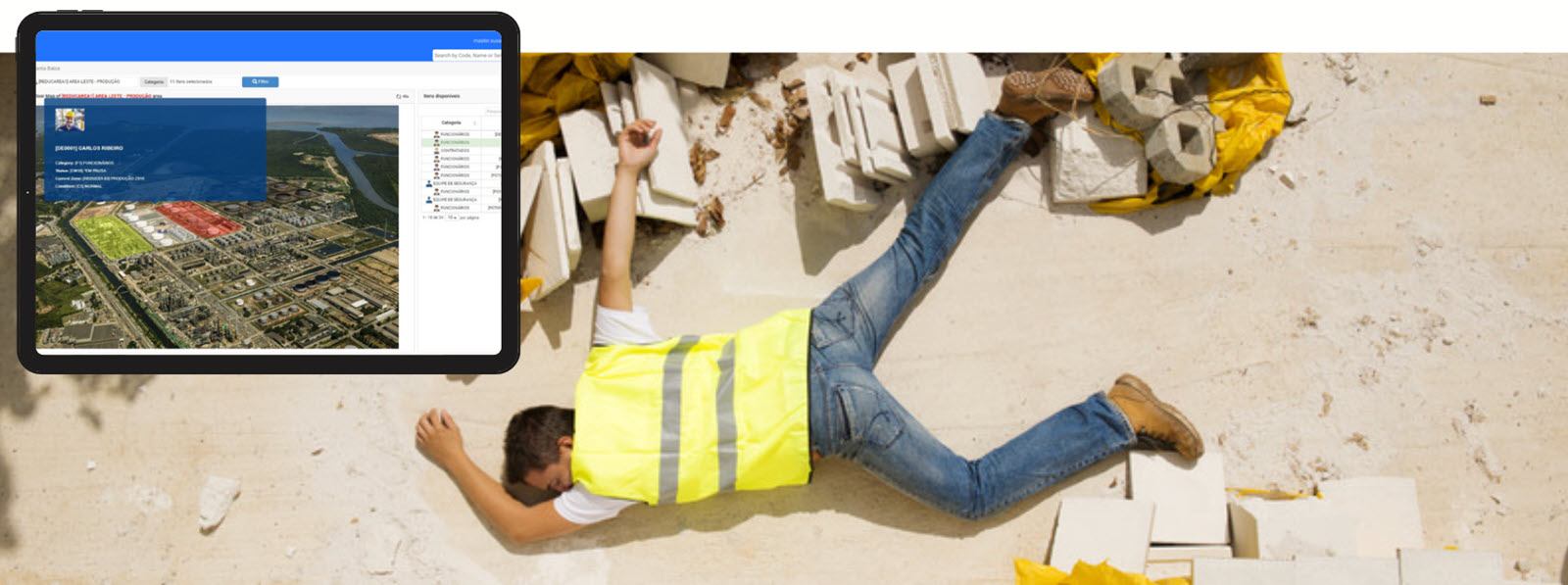

A revolutionary convergence of personal and process safety that improve efficiency, safety and reliability.

The standards outlined in Section 3395 are applicable across various industries, aiming to mitigate the occurrence of heat-induced health issues. These regulations encompass sectors such as agriculture, construction, landscaping, oil and gas extraction, and transportation or delivery of heavy materials like agricultural and construction products.

The Department of Industrial Relations (DIR) has provided a Q&A document to assist individuals in determining if their workplace falls under these regulations.

According to the guidelines, an outdoor place of employment is defined as any space that is not enclosed. This includes open areas like agricultural fields, forests, parks, equipment and storage yards, outdoor utility installations, tarmacs, and roads. Construction sites without completed building shells and areas outside any existing building shells are also considered outdoor workplaces. Additionally, outdoor areas adjacent to buildings, such as loading docks, are classified as outdoor places of employment if employees spend a substantial amount of time working in these areas.

Structures like sheds, packing sheds, and partial or temporary constructions such as tents, lean-tos, and structures with open sides can be either indoor or outdoor workplaces based on specific conditions. In some instances, these structures might be hotter than the environment outside due to factors like sun exposure and limited air circulation. DOSH (The Department of Occupational Safety and Health) considers a structure in this category as an outdoor workplace if it does not significantly mitigate the environmental risk factors present immediately outside the structure.(http://www.fels.net/Data/Laws/CalOSHA-Heat-Illness-2009-QandA-Guidelines.pdf)

The standard also sets forth rigorous emergency response procedures. Employers are required to establish an effective communication system, enabling employees to contact a supervisor or emergency medical services as needed. The use of electronic devices for this purpose is allowed only when there is reliable reception in the work area. If reception is not dependable, the employer must ensure alternative methods for summoning emergency medical services.

Additionally, it is vital for the employer to ensure that clear and simple instructions to the work site are readily available and can be promptly relayed to emergency responders in the event of an emergency.

On April 7, 2015, DIR, in conjunction with Cal/OSHA, announced that major revisions to California’s heat illness prevention standard had been approved by the Office of Administrative Law. The revised standard took effect on May 1, 2015.

Water must be “fresh, pure and suitably cool” and located as close as practicable to where employees are working, with exceptions when employers can demonstrate infeasibility.

· Shade must be present at 80 degrees (26.6°C), instead of the current 85 degrees (29.4°C), and accommodate all employees on recovery or rest periods, and those onsite taking meal periods.

· Employees taking a “preventative cool-down rest” must be monitored for symptoms of heat illness, encouraged to remain in the shade and not ordered back to work until symptoms are gone. Employees with symptoms must be provided appropriate first aid or emergency response.

· High-heat procedures (which will remain triggered at 95 degrees (35°C)) shall ensure “effective” observation and monitoring, including regular communication with employees working by themselves.

· Emergency response procedures include effective communication, response to signs and symptoms of heat illness and procedures for contacting emergency responders to help stricken workers.(http://www.arcamca.org/PDFs/Heat-Illness-Prevention.pdf)

Federal and local laws persistently advocate for employee safety, with a growing emphasis on implementing panic buttons for safety teams. Regrettably, in the budgets of numerous corporations, Employee Safety Devices (ESDs) often remain a low priority.

However, if you are truly committed to elevating your company's standards, investing in ESDs is highly advisable. Here are several advantages of equipping your team with these devices.

A worker safety device is a tool designed to enable workers to communicate with others and be monitored while performing their job tasks.

These devices can monitor employees while they travel to and from locations and offer protection when workers interact with unfamiliar clients or engage in risky operations alone on a site. Some standard functions of these safety devices include:

These devices ensure communication is readily available when needed and can detect any signs of imminent danger, enhancing the safety of lone workers.

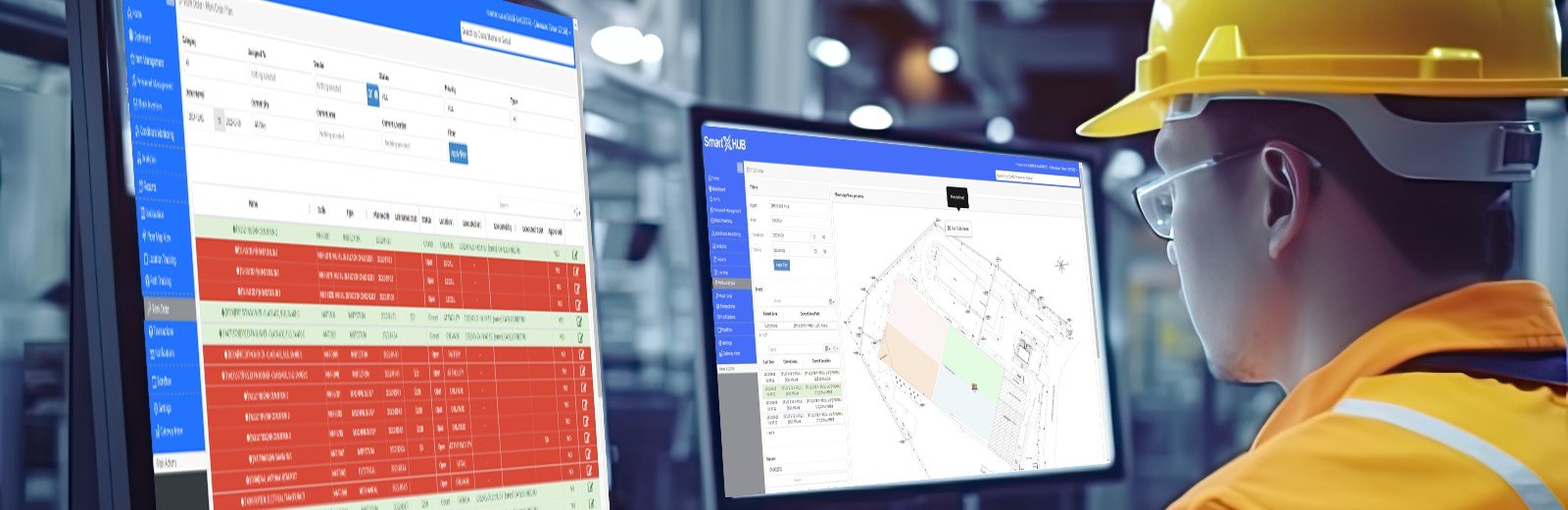

Connected safety solutions encompass a network of cloud-connected devices, including area monitors and personal wearable devices. When integrated with an online dashboard, these devices offer comprehensive insight into the safety of both facilities and personnel.

The data streamed by these devices empowers managers with robust reporting capabilities at their fingertips. Additionally, it monitors the devices' operational status, ensuring they are charged, powered on, and actively used throughout a shift. This valuable information can be accessed from anywhere in real-time, eliminating the need to wait until the devices are docked to receive the data.

Furthermore, through data analysis, these connected safety solutions can identify and predict potential hazards, enabling proactive corrective measures to be taken before they escalate into incidents.

Understanding local legislation is just the beginning of ensuring workplace safety. Now it's time to take proactive steps! Embrace the SmartX HUB system – a leading solution in employee safety monitoring. With our solution, you're not only complying with the laws; you're going above and beyond to create a safer, more secure environment for your workers.

This system is more than just compliance – it's about peace of mind. With SmartX HUB Safety, you can monitor your employees' safety, reduce the risks associated with their tasks, and respond in real-time to any potential dangers.

Whether you're in construction, oil and gas, agriculture, or any other industry requiring extensive outdoor work, SmartX HUB Safety is your safety partner. With its innovative features, it's designed to meet and exceed the requirements of the most stringent safety standards.

The array of solutions offered by SmartX HUB encompasses wearable devices, personal and area attendance monitoring, cloud-connected software, and advanced data analytics. These solutions are meticulously crafted to not only confront safety challenges head-on but also elevate overall productivity levels. With a global presence spanning more than 20 countries, SmartX HUB ensures constant cellular connectivity, serving as a vital lifeline for individuals in various contexts.

For further information, please visit smartxhub.com/contact, and stay connected with SmartX HUB on social media platforms including Facebook, Twitter, LinkedIn, and Instagram.

Contact us at the SmartX office nearest to you or submit a business inquiry online.

Let us know how we can help you solve your business challenges!

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

IoT Ecosystem Empowerment: Advancing Workplace Safety and Efficiency with RTLS The Internet of Things (IoT) has arrived In the dynamic

California’s regulations for preventing heat-related illness in outdoor workers Introduction In situations involving high temperatures or extreme heat, it is

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.