Manufacturing Automation Optimized With RFID

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

Track asset performance, execute maintenance and service, and maximize uptime with advanced technologies.

Deliver as promised with risk-resilient, reliable, and sustainable logistics operations.

A revolutionary convergence of personal and process safety that improve efficiency, safety and reliability.

Asset tracking in the oil and gas industry involves monitoring and managing various types of assets, such as equipment, vehicles, pipelines, and storage tanks. The key performance indicators (KPIs) for asset tracking in this industry typically focus on ensuring operational efficiency, maximizing uptime, improving safety, and minimizing costs. Here are some main KPIs for asset tracking in the oil and gas sector:

Asset Utilization: This KPI measures the percentage of time an asset is actively utilized for its intended purpose. It helps identify underutilized assets that may require optimization or reassignment.

Asset Downtime: This KPI tracks the duration and frequency of asset downtime, including scheduled maintenance, unscheduled repairs, and equipment failures. Minimizing asset downtime is crucial for maintaining operational efficiency.

Asset Maintenance Costs: This KPI measures the total cost associated with maintaining assets, including preventive maintenance, repairs, and spare parts. It helps identify areas for cost reduction and optimization in maintenance practices.

Asset Availability: This KPI measures the percentage of time that assets are available and ready for use. It is important to ensure that critical assets are available when needed to avoid disruptions in operations.

Compliance and Safety: KPIs related to compliance and safety track adherence to regulatory requirements and safety standards. This includes metrics such as safety incidents, near misses, compliance with maintenance and inspection schedules, and adherence to safety protocols.

Asset Lifecycle Management: This KPI evaluates the efficiency and effectiveness of managing assets throughout their lifecycle, from acquisition to retirement. It includes metrics such as asset depreciation, replacement costs, and the ability to forecast asset lifespan.

Inventory Accuracy: This KPI measures the accuracy of inventory records and the ability to track assets in real-time. It helps identify discrepancies, reduce inventory carrying costs, and optimize inventory management processes.

Asset Tracking Accuracy: This KPI measures the accuracy of asset tracking systems, such as GPS or RFID-based technologies. It ensures that assets can be located and monitored accurately, especially in large and remote oil and gas operations.

Asset Health and Condition: This KPI focuses on monitoring the health and condition of assets, such as equipment performance metrics, vibration levels, temperature, and pressure readings. It helps identify potential issues before they lead to failures or downtime.

Environmental Impact: This KPI assesses the environmental impact of asset operations, including emissions, waste management, and compliance with environmental regulations.

These KPIs can vary depending on the specific assets being tracked and the operational goals of the oil and gas company. Monitoring and analyzing these KPIs enable organizations to make data-driven decisions, optimize asset utilization, reduce costs, and enhance overall operational performance.

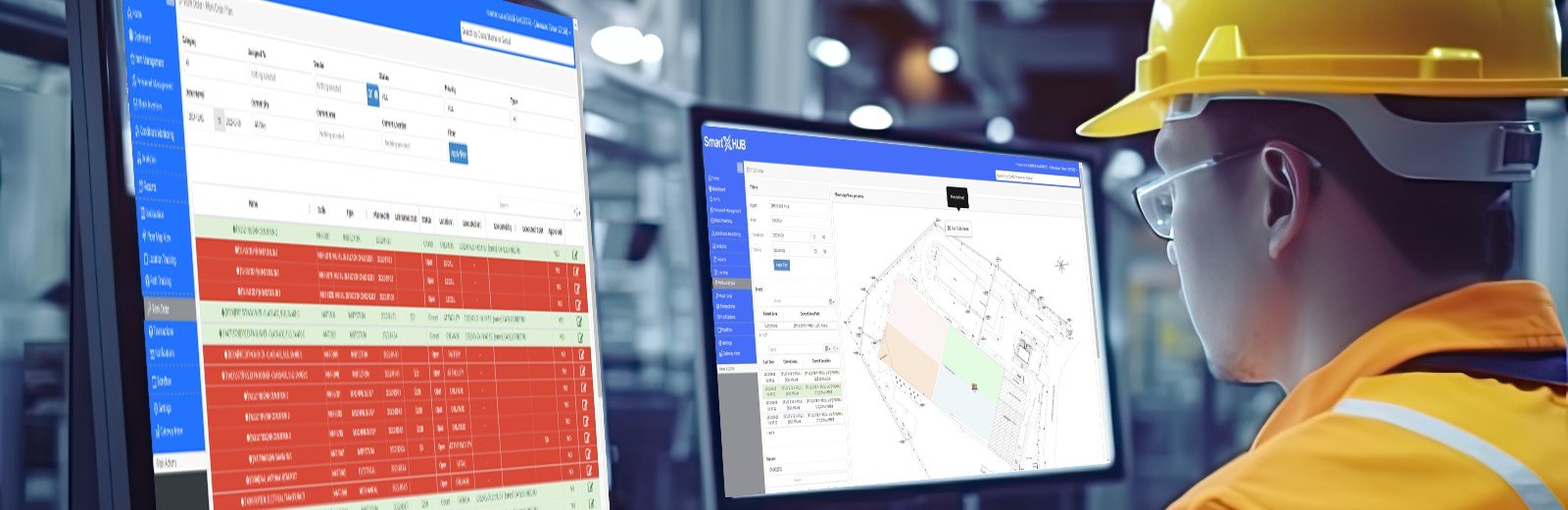

In conclusion, SmartX HUB revolutionizes asset tracking for oil and gas assets, providing a comprehensive and advanced solution for monitoring and managing valuable resources. With SmartX HUB, oil and gas companies can enhance operational efficiency, ensure regulatory compliance, and maximize the lifespan of their assets.

By leveraging cutting-edge technologies such as IoT and real-time tracking systems, SmartX HUB enables precise and accurate monitoring of assets throughout their lifecycle. Every asset can be tracked and managed efficiently, from equipment and vehicles to pipelines and storage tanks.

The benefits of SmartX HUB in asset tracking for the oil and gas industry are numerous. Firstly, it improves operational efficiency by providing real-time visibility into asset location, condition, and utilization. This allows for better planning, scheduling, and resource allocation, resulting in optimized operations and reduced downtime.

Safety is paramount in the oil and gas sector, and SmartX HUB enhances safety measures through asset tracking. By monitoring asset performance and identifying potential issues or anomalies in real-time, preventive maintenance can be scheduled, ensuring the integrity of critical equipment and minimizing the risk of accidents or failures.

SmartX HUB also facilitates regulatory compliance by maintaining accurate records of asset inspections, maintenance activities, and certifications. This ensures that oil and gas companies meet industry standards and adhere to regulatory requirements, avoiding penalties and legal complications.

Moreover, SmartX HUB enables predictive maintenance, leveraging data analytics and machine learning algorithms to identify patterns and trends in asset behavior. By predicting maintenance needs and addressing them proactively, companies can avoid costly breakdowns, extend asset lifespan, and reduce overall maintenance costs.

The comprehensive reporting and analytics capabilities of SmartX HUB provide valuable insights for strategic decision-making. By analyzing asset performance data, companies can identify areas for improvement, optimize asset utilization, and make informed decisions about asset investments and replacements.

SmartX HUB is a game-changing solution for asset tracking in the oil and gas industry. It empowers companies with real-time visibility, improved safety, regulatory compliance, predictive maintenance, and data-driven insights. By harnessing the power of SmartX HUB, oil and gas businesses can streamline operations, enhance efficiency, and drive sustainable growth in a highly competitive industry.

Contact us at the SmartX office nearest to you or submit a business inquiry online.

Let us know how we can help you solve your business challenges!

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

IoT Ecosystem Empowerment: Advancing Workplace Safety and Efficiency with RTLS The Internet of Things (IoT) has arrived In the dynamic

California’s regulations for preventing heat-related illness in outdoor workers Introduction In situations involving high temperatures or extreme heat, it is

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.