Manufacturing Automation Optimized With RFID

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

Production and overall operational efficiency are critical success factors - the ability to ship more products, at a lower cost, with less inventory, in a shorter amount of time can ultimately spell success for a manufacturer. In many cases, though, productivity is slowed or halted due to a lack of visibility of the location and status of inventory, assets, and even people.

Not knowing where the following work in process (WIP) case or carrier is in a large manufacturing facility might lead to longer cycle times and compliance with the production schedule. Lost items stall customer orders and cause unnecessary reproduction and waste. Equipment shared among several programs is often misplaced or missing. Line side inventory needs to be optimized and delivered just in time. Some harsh environments require unique measurements to ensure people’s safety and efficient evacuation and mustering processes during an emergency.

Improper assets and production management lead to severe inefficiencies for the manufacturer, some of which can be addressed through assets traceability:

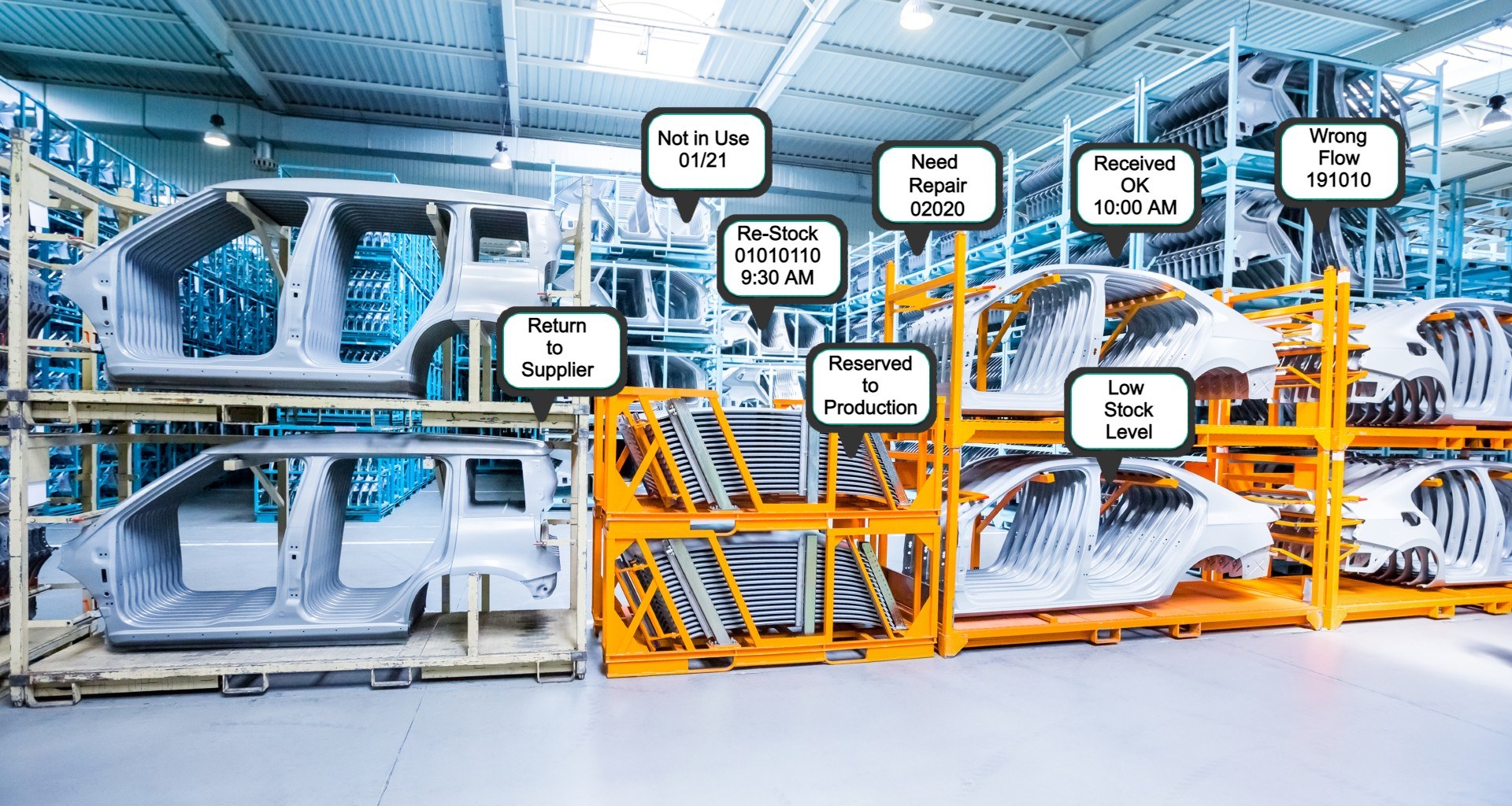

RFID in the automotive industry involves attaching RFID tags to virtually any component of an operation and tracking the tagged assets using RFID software and mobile computers. Auto plant managers can attach RFID tags to tools, containers, parts, shipping boxes and other supplies – allowing even the tiniest of components to be monitored and tracked at all times.

Our Asset Tracking solution leverages analytics, geo-fencing, and IoT-RFID to accurately identify and monitor an asset’s location and movement within an industrial facility.

The following video illustrates this shared, visible accountability of assets and goods flow.

Real-world customer implementations of auto-ID-enabled Asset tracking solutions have demonstrated ROI in less than 12 months. More importantly, these solutions easily integrate into existing business processes to help provide a more seamless implementation and even more value. As early as the first complete turn, companies can leverage data to make smarter decisions, better manage supply chain partners, create process efficiencies and gain more control over the total supply chain costs.

Supply chain information has become increasingly generated by sensors, RFID/ Beacon tags, meters, actuators, GPS, and other devices and systems. In terms of visibility, supply chains are not only able to "see" more events, but they witness them as they occur. They rely less on labor-based tracking and monitoring, as objects like shipping containers, trucks, products, and parts report on themselves. Dashboards on devices display the real-time status of plans, commitments, supply sources, goods inventories, and consumer requirements.

SmartX HUB includes pre-configured reports that allow organizations to manage their asset inventory and utilization more effectively. The SmartX HUB tracking application includes several reports based on information that is, by default, refreshed hourly in the solution.

Here are some of the most apparent benefits of RFID asset management at an automotive plant:

The SmartX HUB RFID-IoT system allows workers to locate tools quickly and easily, preventing the need to stop the assembly line and search for a misplaced tool. It can also help provide insight into how often specific equipment is used, allowing you to control the depreciation of high-value assets better.

Are you concerned that you’re running low on supplies and don’t have time to do an inventory? With SmartX HUB RFID, this problem disappears. Automotive managers can get constant visibility into inventory levels and configure their systems to reorder supplies to prevent shortages when supplies run low automatically.

One of the most significant benefits of RFID involves the massive increase in visibility that can be achieved in shipping and receiving. You will know precisely where different items are in your supply chain.

SmartX HUB Integrates real-time, item-level data into existing enterprise shipping and logistics applications, so the data reflected in the system accurately represents what's happening at the loading dock. This accurate information enables logistics teams to make critical business decisions quickly.

Gain item-level data about every asset to ensure essential tools and equipment don't get lost, misplaced, or stolen. You can reduce overall inventory levels by keeping up-to-date on your tools' whereabouts while ensuring adequate supplies across all locations.

Add RFID-enabled tags to reusable shipping containers for automated management of where the containers have gone and when they’ve been returned. Automate the tracking process with reusable containers shipped out and returned to your business.

Traceability technology provides insight into container distribution, status, and supplier performance. SmartX HUB Asset Tracking is part of SmartX’s Solution for Track & Trace and also leverages IoT-RFID, IoT, and Cloud platforms for data capture. Smartx HUB’s Solution for Track & Trace advances its past success in traceability technology by enabling multiple business use cases through applications and business intelligence.

Built on the SmartX HUB Platform, the Asset Visibility and Supply Chain Management applications enable companies to manage their supply chains using new data, offering scorecards, dashboards, and reports to set expectations and identify cycle and turnaround times inadequate performance by trading partners and suppliers.

By automating your processes with SmartX HUB RFID-IoT technology, you can cut daily operational costs by significantly reducing labor and error costs through process automation. SmartX HUB offers a scalable, customizable and straightforward platform, easily fitting into your unique business process. SmartX HUB runs on any web browser and any Windows, iOS, or Android device to make it even easier.

SmartX HUB’s global presence, coupled with its deep industry and business transformation expertise, has proven that the methodologies and experience gained from thousands of worldwide engagements help clients achieve business results and innovation quickly and cost-effectively.

Contact us to get more information on how we can help you overcome the challenges to your manufacturing business or to check out a free demo.

Contact us at the SmartX office nearest to you or submit a business inquiry online.

Let us know how we can help you solve your business challenges!

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

IoT Ecosystem Empowerment: Advancing Workplace Safety and Efficiency with RTLS The Internet of Things (IoT) has arrived In the dynamic

California’s regulations for preventing heat-related illness in outdoor workers Introduction In situations involving high temperatures or extreme heat, it is

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc