Manufacturing Automation Optimized With RFID

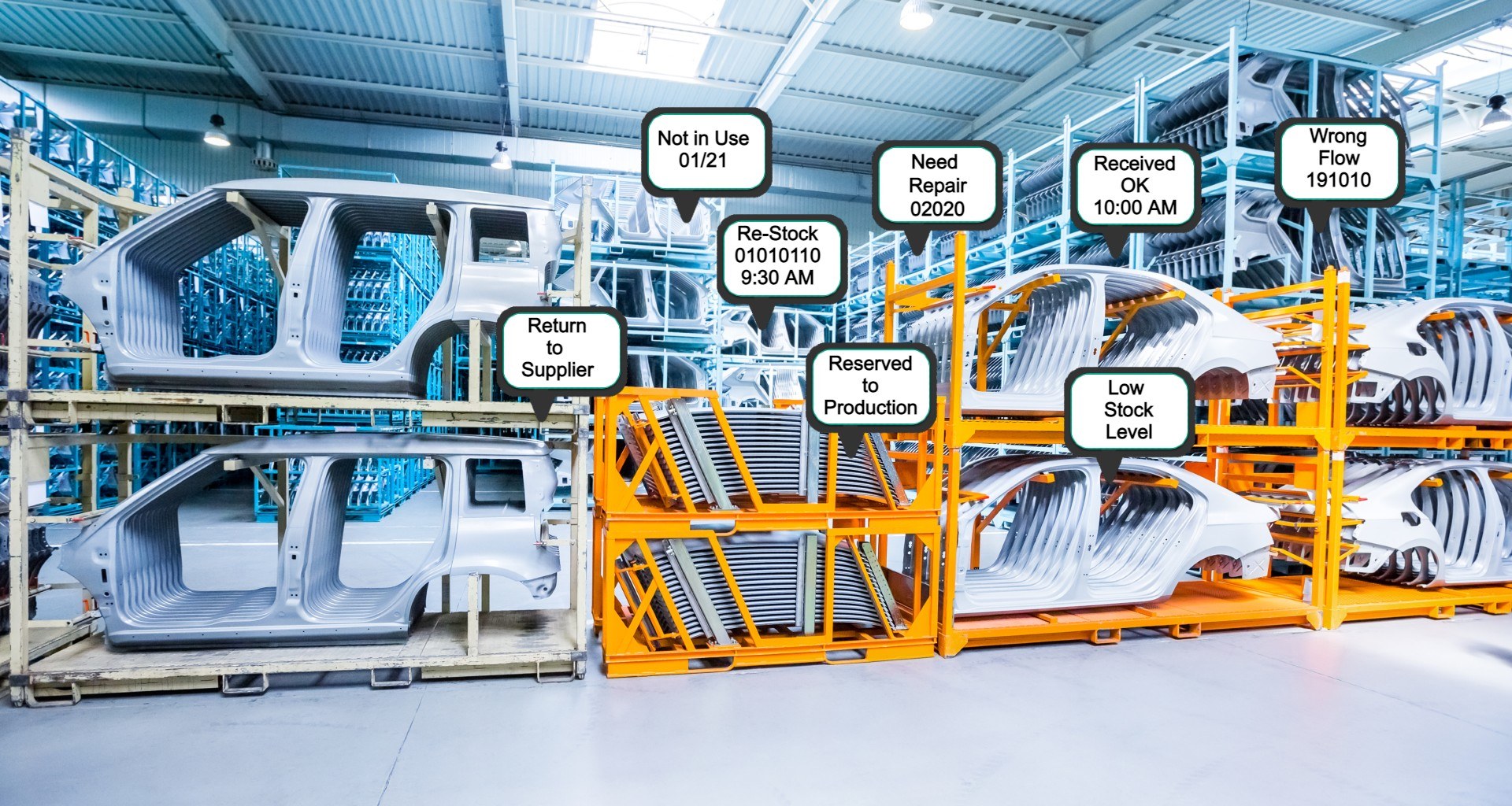

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

Track asset performance, execute maintenance and service, and maximize uptime with advanced technologies.

Deliver as promised with risk-resilient, reliable, and sustainable logistics operations.

A revolutionary convergence of personal and process safety that improve efficiency, safety and reliability.

There are a number of advantages to using RFID technology. Not only are RFID systems contactless, but they also do not require line of sight like other auto ID technologies. For different applications spanning various industries, RFID technologies offer a long-term and durable solutions for better asset management and tracking

RFID systems are made of three main components: tags, readers and middleware.

-Tags are essentially small memory banks, storing bit of valuable information that can be used for asset management and a variety of other purposes. They use radio waves to communicate with nearby readers, sending over portions of identifying data. The information sored in RFID tags can range anywhere from a single serial number to multiple pages of data.

- Readers, on the other hand, are basically the other end of the information exchange. They are what we use to take those radio waves from the tags and translate them back into useful data. Readers are devices with one or more antennas that can emit their own radio waves and scan the signals of any RFID tags within range.

- RFID readers offer some versatility depending on the needs of your application. You can have mobile readers that you can carry around in your hand to scan tags, or they can be mounted in a single location to scan tags that enter their proximity. Readers can even be built into existing architecture like a cabinet or doorway.

- Middleware serves as the essential interface between the reader and your company databases and information management software. Not only does middleware handle communication between the reader and your existing systems, but it also helps to filter, aggregate and interpret all of that data coming from the RFID tags.

SmartX HUB Solution helps you obtain a more efficient workflow by improving your control over your project, enhancing safety on your Jobsite, reducing equipment downtime, minimizing safety hazards, increasing equipment life expectancy, and reducing repair costs. It provides you with the necessary means to stay on schedule, stay on budget and work consistently to keep your overall project on the right track.

The solutions, like SmartX HUB’s RFID, are fully automated, enabling workers to quickly get and return the assets they require without an asset attendant while keeping the employee accountable.

By automating your processes with SmartX HUB RFID-IoT technology, you can cut daily operational costs by significantly reducing labor and error costs through process automation. SmartX HUB offers a scalable, customizable and straightforward platform, easily fitting into your unique business process. To make it even easier, SmartX HUB runs on any web browser and any Windows, iOS, or Android device.

SmartX HUB’s global presence, coupled with its deep industry and business transformation expertise, has proven that the methodologies and experience gained from thousands of worldwide engagements help clients achieve real business results and innovation quickly and cost-effectively.

Contact us to get more information on how we can help you overcome the challenges to your construction business or to check out a free demo.

Contact us at the SmartX office nearest to you or submit a business inquiry online.

Let us know how we can help you solve your business challenges!

Manufacturing Automation Optimized With RFID RFID tags facilitate the seamless transmission of data alongside a product, enriching the information as

IoT Ecosystem Empowerment: Advancing Workplace Safety and Efficiency with RTLS The Internet of Things (IoT) has arrived In the dynamic

California’s regulations for preventing heat-related illness in outdoor workers Introduction In situations involving high temperatures or extreme heat, it is

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.