Reduce operational costs and maximize output through connected AIoT Technology

Keep your workforce safe and projects productive.

THE PERFECT RTLS IoT-RFID BASED AND AI

Mining Asset Management with Real-Time Location and AI

Our solution for advanced tracking of workers and assets in harsh environments, integrates seamlessly with existing software and is flexible to suit your operational needs. It has been specifically developed for those operating in remote environments.

Our multi-technology solution can process data from RFID, Lora, Mesh, GPS, BLE and other technologies to identify, locate and monitor assets and people.

Our workplace safety solutions deliver the critical intelligence and alerts necessary to maintain a secure operational environment and protect your workforce.

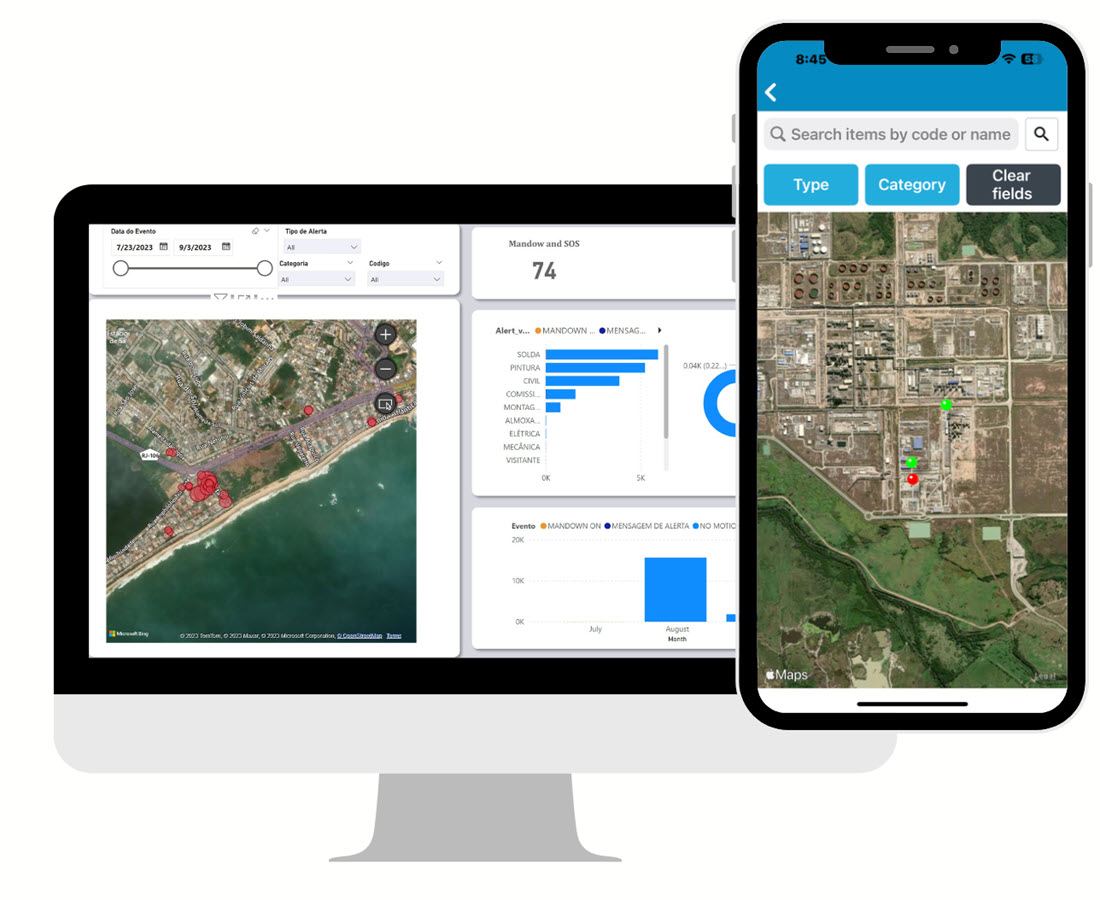

In mining, reliable communication and real-time data are key to safety and efficiency. Smartx HUB provides centralized monitoring of equipment, vehicles, and workers through integrated RFID, IoT sensors, and GPS tracking. With advanced RTLS and predictive analytics, operators can identify risks early, optimize machine uptime, ensure proactive maintenance, and enhance worker safety—supported by automated alerts and real-time dashboards.

Connected worker, processes, and assets and keep compliance on projects and mining jobsites.

The Smartx HUB platform seamlessly integrates with equipment, software, IoT sensors, and other sources, enabling remote monitoring and real-time data visualization from a single command center. This technology-driven platform offers data-driven decision-making capabilities through AI-based predictive analytics and insights. By consolidating reliable data into a central source, it monitors and tracks workers, equipment, tasks, and maintenance procedures, improving operational performance, enabling rapid response, and ensuring correct actions for a safe and efficient environment.

Our Services

Asset Management

Manage heavy machinery and mining assets from purchase to decommissioning. Track usage, maintenance, and compliance to maximize equipment lifespan and minimize downtime in remote and harsh environments.

Real-time Asset Location

Monitor the exact location of vehicles, tools, and equipment underground or on-site. Real-time tracking improves efficiency and reduces loss or misplacement in complex mining environments.

Predictive Maintenance & Condition Monitoring

Prevent costly breakdowns of critical mining machinery. IoT sensors provide real-time data on asset health, enabling predictive maintenance for continuous operation.

Work Order Management

Our robust work order management system allows teams to create, prioritize, and track maintenance activities. Automated workflows help streamline tasks, while real-time tracking ensures that work orders are executed efficiently, reducing asset downtime

Digital Inspections & Workflow Automation

Conduct digital inspections of equipment and infrastructure. Automate work orders and compliance tasks to ensure operational consistency.

Workforce Safety & Compliance

Protect miners with real-time personnel tracking in high-risk areas. Automate safety checks, track PPE usage, and ensure regulatory compliance through instant alerts.

Environmental & Sustainability Monitoring

Track air quality, vibration, noise, and other environmental factors. Ensure regulatory compliance and reduce ecological impact with real-time monitoring.

Logistics & Supply Chain Optimization

Streamline the movement of raw materials, spare parts, and fuel across the site. Automate inventory tracking and delivery processes to reduce delays.

Enterprise Integration & Scalability

Connect and grow with flexible, scalable solutions designed for enterprise needs. API-driven integrations link to your ERP and cloud platforms, supporting multi-site operations with secure, role-based access.

Smartx HUb is the only data-driven, interconnected, real-time data visualizationsolution to keep people safe and business thriving

Leverage data to optimize mining operations, from equipment usage to workforce allocation. Custom dashboards provide insights that drive productivity and cost reduction.

The connectivity and software to further protect your team

Real-Time Monitoring Across the Mine

Track vehicles, equipment, and personnel with connected IoT and GPS solutions, ensuring complete visibility in even the most remote locations.

Proactive Risk Detection and Alerts

Identify hazards early with data-driven insights. Automated alerts help prevent incidents and ensure compliance with mining safety standards.

Optimized Equipment Uptime

Leverage predictive maintenance to reduce unexpected breakdowns, improving efficiency and extending the life of critical mining assets.

Centralized Control and Analytics

Access all operational data in one platform. Smartx HUB delivers powerful analytics to support fast decisions and safer, more efficient operations.

Safety beyond compliance.

With Smartx HUB's connected safety solutions and data, you can review workers' risk exposure reports, analyze heat maps of hazardous incident locations, and track compliance trends over time. Unsure about the current calibration status of every critical asset in your operation? Smartx HUB provides real-time visibility into every connected device, enabling you to ensure the safety of your workers. With connected wearables that deliver data analytics for real-time compliance, you can be confident that you are not only compliant but also proactively improving the safety of your team.

Efficiently manage your workforce and trade partners using safety wearables, smart sensors, and a workforce management platform.

Efficient Yard Management for Mining: Maximize Control of Assets, Trucks, and Materials

Manage the complexity of your mining yard with real-time visibility of parts, trucks, and critical assets.

Smartx HUB uses RFID, IoT sensors, GPS tracking, and RTLS to streamline operations.

Track movements, optimize logistics, and reduce asset loss with automated alerts and real-time dashboards. Drive productivity with smarter, data-driven yard operations.

Our software provides companies with real-time visibility of assets meaning a significant reduction in the number of items that are misplaced.