Smarter Facilities. Connected Assets. Safer People. AIoT-RFID Technology

Keep your workforce safe and projects productive.

THE PERFECT RTLS IoT-RFID BASED AND AI

Smarter Operations. Connected Production. Real-Time Supply Chain Visibility.

Maintain high standards with real-time tracking. Spot issues early, reduce rework, and meet compliance to ensure consistent product quality.

Uptime

Minimize downtime with real-time insights.

Give your team the tools to act fast, boost efficiency, and keep production on track.

Digitize Your Shop Floor. Streamline Supply Chain. Empower Smart Manufacturing.

SmartX HUB®’s connected platform delivers real-time visibility, automation, and workforce enablement across the entire production lifecycle. By empowering teams, tracking assets in real time, and digitizing critical workflows, manufacturers can minimize downtime, prevent material loss, and elevate operational efficiency. With actionable insights at every stage—from inbound logistics to final assembly—SmartX HUB helps build operational resilience, maintain top-quality standards, and drive sustainable growth in today’s competitive manufacturing landscape.

Core Capabilities for Manufacturing Excellence

Real-Time Inventory Tracking

Track WIP, components, tools, RTIs, and finished goods with RFID and BLE technologies across production cells and warehouses. Ensure the right parts are at the right place at the right time.right place at the right time.

Production Line Part Verification

Ensure correct part usage during assembly by scanning components with RFID or barcode devices. Prevent errors, rework, and production delays.

Work-in-Process (WIP) Tracking

Monitor parts and sub-assemblies in real-time as they move across stations. Reduce bottlenecks and gain visibility into cycle times.

Returnable Transport Items (RTI) Management

Track reusable racks, bins, and pallets to reduce losses and optimize circulation. Receive alerts on idle RTIs and turnaround delays.

Inbound & Outbound Logistics Automation

Automate gate reads, shipment verification, and inventory receipts using fixed RFID infrastructure at docks and checkpoints.

Risk Management

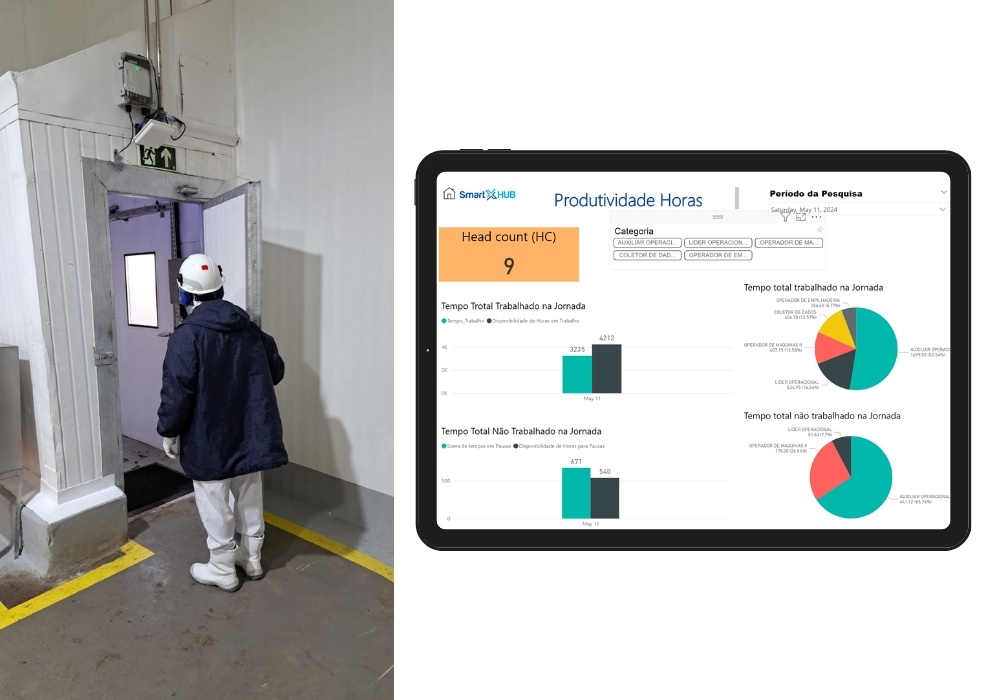

Performance analytics and asset’s operational status for a clear view of the operation and accurate risk assessment.

Tool & Fixture Tracking

Track usage, movement, and calibration status of critical tools and fixtures. Prevent production halts due to missing or expired tools.

Condition Monitoring (Sensors & IoT)

Monitor temperature, humidity, vibration, and more to protect sensitive equipment and materials.Receive alerts before failures occur.

Workforce Safety & Certification Control

Use RFID badges and zone tracking to verify personnel in restricted areas and confirm operator certifications before machine use.

Smartx HUb is the only data-driven, interconnected, real-time data visualizationsolution to keep people safe and business thriving

Our SaaS-based Safety 4.0® platform offers predictive AI-powered digital safety solutions with a real-time view of a plant’s operational reality with superior visualization and dynamic work activities and risk management

Whether you're tracking components across assembly lines and software to further protect your team. , verifying tools and parts, conducting facility rounds, or automating warehouse workflows

Speed

Reduce manual handling and improve operational efficiency. Streamline workflows, minimize disruptions, and ensure production stays on schedule with automated material handling.

Uptime

Maximizing uptime by ensuring critical tools, equipment, and materials are always available when and where they are needed to keep operations running smoothly.

Accuracy

Accurately tracking asset locations and usage helps reduce losses, maintain proper inventory levels, and support effective decision-making.

Efficiency

Improving efficiency by automating asset management processes, reducing manual effort, and minimizing disruptions throughout the production process.

Next-level safety

The SmartX HUB online portal enables you to manage your connected safety devices, monitor your facility and workforce well-being in real-time, respond to emergencies, and generate reports from collected data. Simple compliance is no longer sufficient.

Streamline Material Flow with Flexible Automation

Real-time visibility ensures materials arrive on time, keeping lines running smoothly and operations efficient. Whether it’s lineside replenishment, intralogistics, or automated removal, our solutions eliminate errors and optimize your material flow. SmartX HUB’s automated material handling solutions provide visibility into inventories to keep workflows seamless. With fewer manual tasks, you’ll improve efficiency, lower costs, and ensure smooth, timely movement of parts and materials.

Efficiently manage your workforce and trade partners using safety wearables, smart sensors, and a workforce management platform.

Track Progress with Real-Time WIP Insights

SmartX HUB® enables end-to-end visibility and tracking across the entire plant floor, giving manufacturers real-time insight into every stage of production. Identify bottlenecks early, respond with data-driven decisions, and optimize workflows to keep operations running at peak performance. With seamless WIP tracking and Industry 4.0-ready integration, SmartX HUB streamlines production, enhances quality control, and unlocks new levels of efficiency—eliminating guesswork and driving continuous improvement from start to finish.

See every step of production in real time. Track parts, products, and inventory as they move through processes to keep operations smooth and efficient.

Connected worker, processes, and assets and keep compliance on production and warehouse sites.

SmartX HUB’s safety solution breaks down information silos, providing dynamic risk management and process safety through enhanced connectivity in the manufacturing environment. The SmartX HUB platform fully integrates with equipment, software, IoT, sensors, and other sources, enabling remote monitoring and real-time data visualization from a single command center. This technology-based platform offers data-driven decision-making with AI-based preventive analytics and insights. By consolidating reliable data, it monitors and tracks workers, equipment, tasks, and maintenance procedures to improve operational performance, enable fast responses, and ensure correct actions for an efficient and safe manufacturing environment.