Track every movement. Gain full control. Optimize your operations. All with RFID Technology

So that you can focus on your maintenance strategy and productivity.

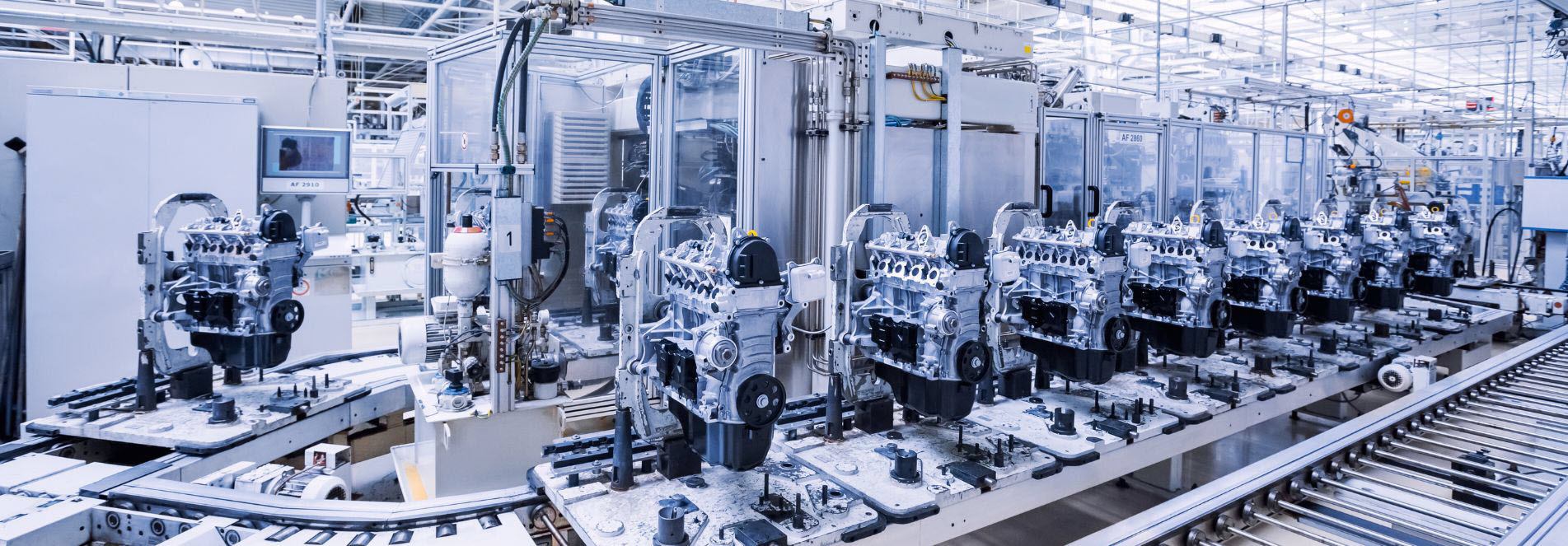

Extending IoT to Every Thing in Manufacturing and Automotive Industries with RFID

Managing work-in-progress materials across dynamic environments is critical to production speed, inventory accuracy, and operational efficiency. Smartx HUB’s RFID-powered WIP tracking solution delivers end-to-end visibility across conveyors, beltways, workstations, and storage zones.

Gain real-time visibility into the status of each assembly project, helping managers stay aligned and customers stay informed throughout the process. Empower your assembly lines with data-driven agility that keeps operations efficient and customers one step ahead.

Optimize your manufacturing business with tracking technologies

In today’s competitive manufacturing landscape, reducing waste, improving efficiency, and cutting unnecessary costs are more critical than ever. Smartx HUB helps you stay lean and agile by giving you real-time visibility into your inventory, tools, parts, and even personnel.

By leveraging advanced technologies like RFID, BLE, AoA, LoRa, and GPS, we deliver accurate, real-time location data that eliminates guesswork and downtime.

Work-in-Progress (WIP) Tracking. Keep production moving with real-time visibility

In manufacturing, efficient work-in-progress (WIP) tracking is critical to maintaining production flow and minimizing downtime. Smartx HUB delivers real-time visibility into every stage of the process, allowing managers and operators to monitor item movement, identify delays, and ensure operations stay on schedule.

Our RFID-enabled WIP tracking solution enhances product traceability, improves inventory accuracy, and reduces the need for excess stock. With live data at your fingertips, you can make faster, smarter decisions that boost efficiency, product quality, and overall profitability.

Worker Automation and Task Management

Improving productivity starts with empowering your workforce. Smartx HUB helps streamline operations by giving employees real-time access to the information and tools they need to perform tasks more efficiently. From the warehouse to the production line, our platform enables smarter decision-making and faster execution.

Whether it's automating Kanban workflows for rapid stock replenishment, optimizing forklift routes to reduce idle time, or tracking tasks and KPIs across teams, Smartx HUB delivers the visibility and control needed to boost efficiency and performance at every level of your operation.

Our Services

Real-Time Production Visibility

Monitor the exact location and status of items as they move through the production process. Improve traceability and identify bottlenecks instantly to keep workflows running smoothly.

Digital Work Order Management

Keep track of work across your organization by creating, assigning, and prioritizing digital tasks. Plan preventive maintenance and respond to one-off requests with full operational oversight.

Automated Inventory Control

Track raw materials, components, and finished goods with RFID and IoT. Maintain accurate inventory levels, avoid overstocking, and support lean operations.

Staff Uniform and Equipment Tracking

Ensure full control of issued uniforms and equipment through tag-based tracking. Reduce loss, improve accountability, and automate inventory counts across shifts.

Production Line Efficiency Analytics

Capture and analyze performance data from each production stage. Identify slowdowns, optimize throughput, and drive continuous improvement with live KPIs.

Seamless Integration with Supply Chain Systems

Link production data to your ERP, MES, or WMS to create a unified operation. Ensure data consistency across departments and streamline cross-functional workflows.

Optimize inventory and deliver customized products

With real-time data on each part’s location and stage in the process, manufacturers can optimize inventory levels and ensure timely replenishment. This prevents costly downtime caused by parts shortages and keeps production moving. Increased visibility also supports greater flexibility, enabling the efficient delivery of customized products.

Achieve Seamless Production with Real-Time WIP Visibility

See every step of production in real time.

Track parts, products, and inventory as they move through each stage to keep operations seamless, efficient, and fully under control.

Track with precision. Deliver with confidence.

Maintain high standards with real-time tracking. Detect issues early, minimize rework, and ensure compliance to consistently deliver products that meet your quality expectations.

Minimize downtime with real-time insights.

Empower your team to respond quickly, improve efficiency, and maintain a smooth, uninterrupted production flow.

Total Visibility, Smarter Decisions

Our technology provides complete identification and tracking across the plant floor, delivering real-time insights into every stage of production. Eliminate bottlenecks, streamline workflows, and make data-driven adjustments to boost efficiency, maintain quality, and stay ahead in your Industry 4.0 journey.

What's more? Authenticate Products Automatically, in Real Time

Counterfeit goods damage brand reputation, waste resources, and pose safety risks. With Smartx HUB's real-time product authentication solutions, powered by advanced RFID technologies, companies can instantly verify the authenticity of items as they move through the supply chain.

Our system ensures automatic, hands-free validation of products made from textiles, plastics, metals, ceramics, and glass—helping protect your brand, secure your inventory, and build customer trust. Seamlessly extend your existing RFID infrastructure to include brand protection without disrupting operations.