- Solutions

- Industries

- IoT Platform

asset management

security

- Resources

Resources

Products

Success Stories

RTLS Fundamentals

- Blog

- About

- En-US

The Manufacturing Vision Study 2017 (Zebra.com) that 62% of manufacturers worldwide still use spreadsheet-based methods to track their assets. However, by 2022 this figure is expected to drop to 20% due to the further development of smart asset tracking solutions.

Every year, companies lose thousands to millions of dollars per establishment simply because they are not accurately tracking and measuring their assets, such as supplies, computers, and high-value equipment.

By providing valuable information about assets’ statuses, locations, and flows, they remove the tracking burden from employees and eliminate errors bound to the manual methods of data input.

In this article, we will share our experience and dwell on the technologies that help to achieve a remarkably higher level of asset tracking visibility and automation.

Before we dive into what a smart approach to asset tracking implies, we have to understand what level of visibility and automation the majority of enterprises currently possess. Let’s look at an example.

For example, one construction company owns hundreds of durables ranging from cement mixers to backhoe loaders. These durables move from a central warehouse to, say, fifty construction sites a year. The company needs to track what construction site each durable is located at, how it is utilized, who operates it, etc. For that, the employees take notes about the activities performed with the assets on a notepad and then enter the data into a spreadsheet.

Considering the number of durable assets, construction sites, and operations performed on each machine, imagine how much time the company loses on tracking (not to mention the fact that about 88% of spreadsheets contain errors).

Without software to track and manage assets, companies are only left with the option of manually recording and handling inventory using spreadsheets or even regular text documents. Unfortunately, manual asset tracking results in a decrease in both productivity and efficiency across the entire establishment. For example, manually entering and tracking assets uses up lots of time, as does doing audits by hand instead of automating them with asset software. Such time could be saved and put to better use in advancing the laboratory institution’s goals and needs if employees were freed up from manual asset management.

Enterprises turn to IoT solutions to implement asset-tracking solutions, as Industrial IoT and RFID are the main players in the field of smart asset management. Here is a quick intro into each:

RFID systems consist of three components: RFID tags, RFID antennas, and RFID readers.

RFID TAG

ANTENNAS

RFID HANDHELD

RFID TAGS

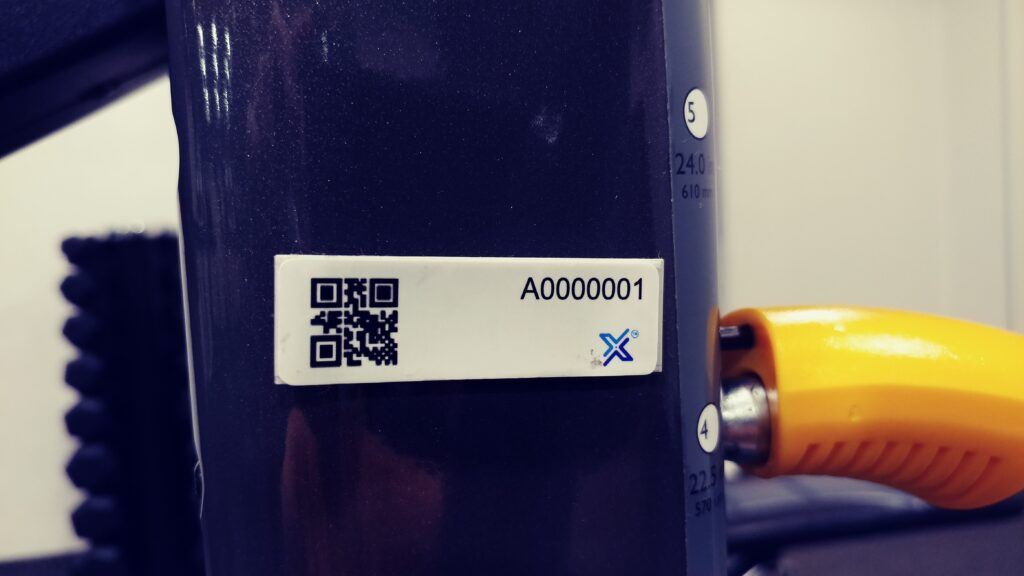

An RFID tag can be attached to any physical surface – from raw materials and components to handheld tools and large movable equipment. Each tag has an ID, carrying the data about an object the tag is attached to. For industrial purposes, mainly passive tags are used, i.e., those without their own power supply. Such tags are quite cheap, but they need to be powered by the reader to be able to transmit data.

RFID ANTENNAS

An RFID antenna catches radio waves from the reader to ‘feed’ the tags with the energy required for operations and relays the radio signal emitted by the tags back to the readers.

RFID READERS

RFID readers – be they handheld or fixed – use radio waves to write to and read from the tags. They can simultaneously read from the number of tags over distance. A reader catches the tags’ IDs and transmits them, as well as the data about the reader’s location and the time of the reading, to the cloud for storing and processing.

Smart asset tracking can be applied to track both lightweight tools and heavy machinery. For that, each movable asset – be it a drill or a bulldozer – gets a passive RFID tag. Each tag has an ID that carries encoded data about the asset it is attached to, e.g., its description, manufacturer, cost, condition, model, serial number, an assigned employee, location, etc.

This data is saved to the SmartX HUB data warehouse – and in-cloud data storage – upon authorizing a tag. To authorize the tag, an equipment storage yard worker scans it with a handheld RFID reader and enters the asset data via an asset tracking app. The asset tracking app forwards the data to the Platform, where the data record is stored with an “authorized” label. Once the tag is authorized, the asset tracking software receives a command to track the tag.

To enable tracking, fixed RFID readers are installed to scan the tags at the checkout area of a tool zone, at the exits of equipment storage yards, at the entrances of construction sites, and other key points.

When passively tagged movable assets leave a tool zone or an equipment storage yard, the RFID reader scans tags’ IDs at the exit and relays them to the cloud. The cloud aggregates the data from multiple readers, runs it through analytics algorithms, and identifies that the movables with the corresponding IDs have left the tool zone or the equipment storage yard. SmartX HUB Cloud software updates the data about the corresponding items in the big data warehouse and displays the updates to the users.

As the movable equipment enters the construction site, the RFID readers installed at the entrances, capture tags’ IDs and relay them to the cloud to check if all the machines and tools have arrived at the construction site.

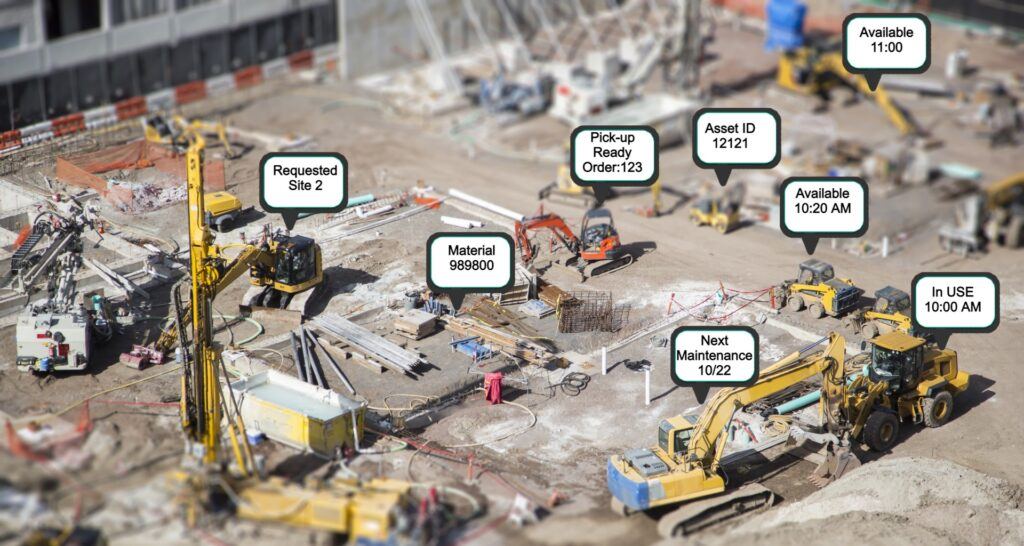

Moreover, thanks to having several high-frequency RFID readers deployed at the key points of the company site, the asset tracking solution provides the employees with real-time data about the movements of durables, as well as their statuses. If a piece of movable equipment leaves the assigned area, is used outside of operating hours or by an unauthorized person, the asset tracking solution sends a notification to an inventory specialist.

IoT-driven asset tracking and inventory management lay a solid foundation for industrial process improvements and enhance the way business works. Let’s see some examples:

Track medical equipment to improve utilization, ensure compliance, and improve the patient experience.

Track tools and construction service equipment to lower cost and streamline service. The construction crew needed the ability to track and trace the construction materials throughout the process.

Automate management of tools and equipment to improve utilization, and streamline maintenance.

Here are just a few benefits that allow enterprises to operate more smoothly:

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc