- Solutions

- Industries

- IoT Platform

asset management

security

- Resources

Resources

Products

Success Stories

RTLS Fundamentals

- Blog

- About

- En-US

Whether it’s a local mold shop or a globally renowned supplier, the need for a centralized system is proving more beneficial to all of the parties involved. Instead of managing information in multiple systems, users should opt for an all-inclusive system to manage information internally and throughout the supply chain, enabling improved collaboration. A decentralized system can negatively influence the success of the work, cost money, increase the likelihood of error or management oversight, and simply complicate the process.

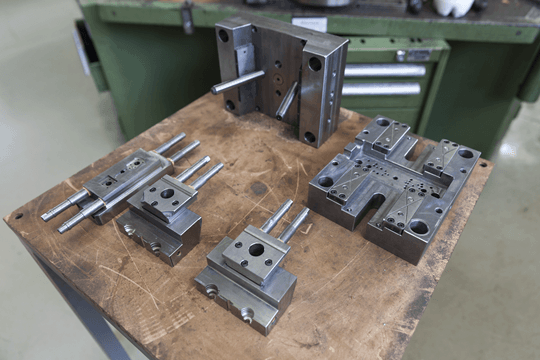

In a high volume/high mix manufacturing environment, they needed to be able to locate tools quickly, verify that the tools identified were the right ones for a given product, and manage their tool maintenance and inspection processes to ensure they were consistently hitting the company’s high quality production standards.

Many manufacturers already rely on data tracking to review order status, cycle-time performance and product quality, but some now are also digitizing their strategies, and producing faster and more accurately while lowering costs and reducing lost time. Location tracking of molds via the cloud is a key component to a centralized system, and using an all-inclusive tool management documentation platform will help provide the necessary tools to do this.

RFID are becoming more commonly used to track tools and assets. Merging such technology with the cloud streamlines communication among multiple positions within a company, makes asset movements information sharing more transparent and readily available, and shortens the approval process. Additionally, when a mold shop receives an OEM request for information on a mold that was completed years prior and that is no longer in the shop, that cloud-based system can provide speedy, convenient access to that information.

With Smartx Hub® RFID solution, you can increase automation and revenues and decrease the percentage of production errors using a track and match applications. There are numerous benefits of using RFID Smart Sensors technology for tools and molds tracking, positively impacting both operational efficiency and safety. Smartx Hub platform should store and share files, but also provide real-time updates, issue reporting, custom alert notifications and GPS location tracking from one centralized system. An app option will also allow a shop’s customers to access their information via the cloud and guarantees that the pertinent tooling data remains with the mold no matter where it travels.

Track the full lifecycle of your Injection Mold Tools.

Automating the management of physical assets saves your organization labor, time and money:

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc