- Solutions

- Industries

- IoT Platform

asset management

security

- Resources

Resources

Products

Success Stories

RTLS Fundamentals

- Blog

- About

- En-US

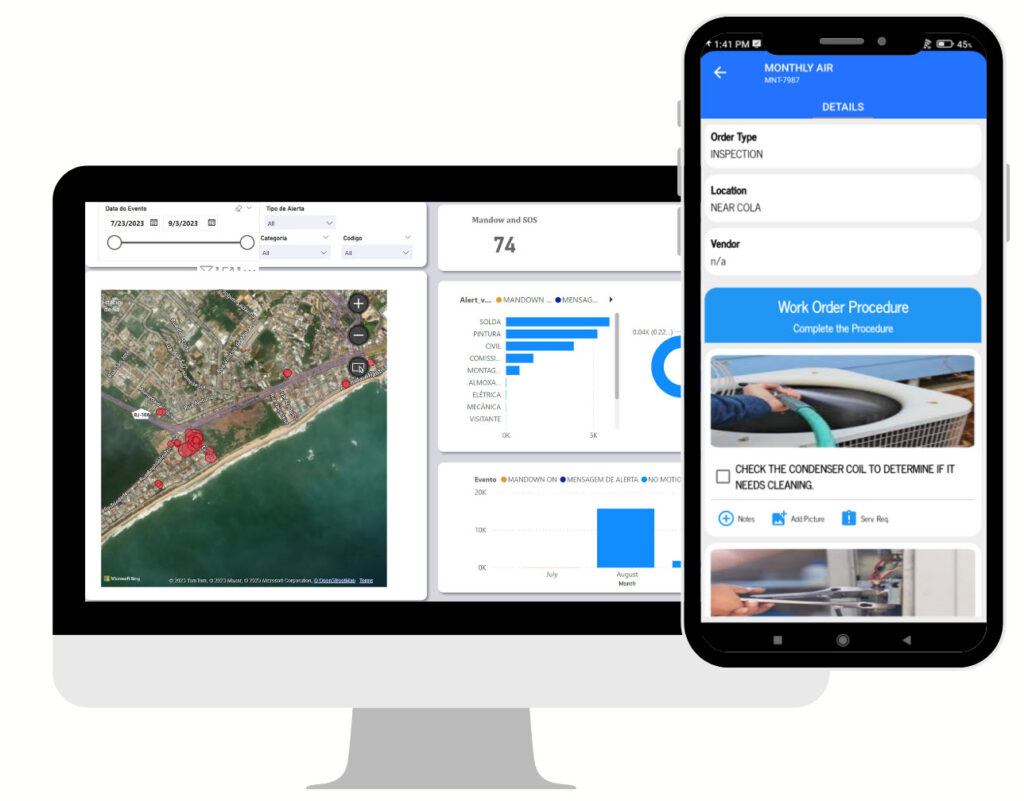

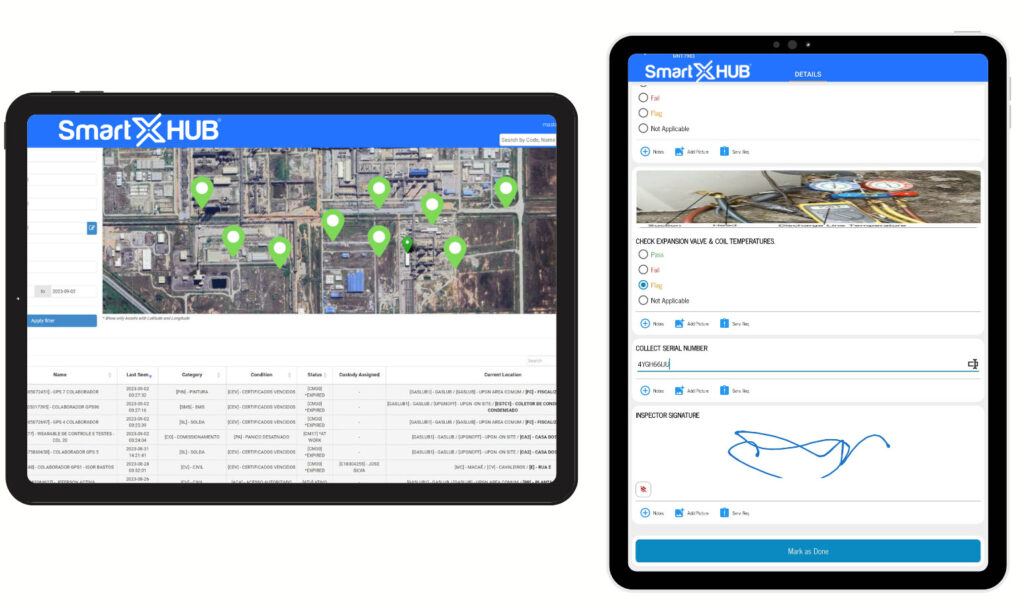

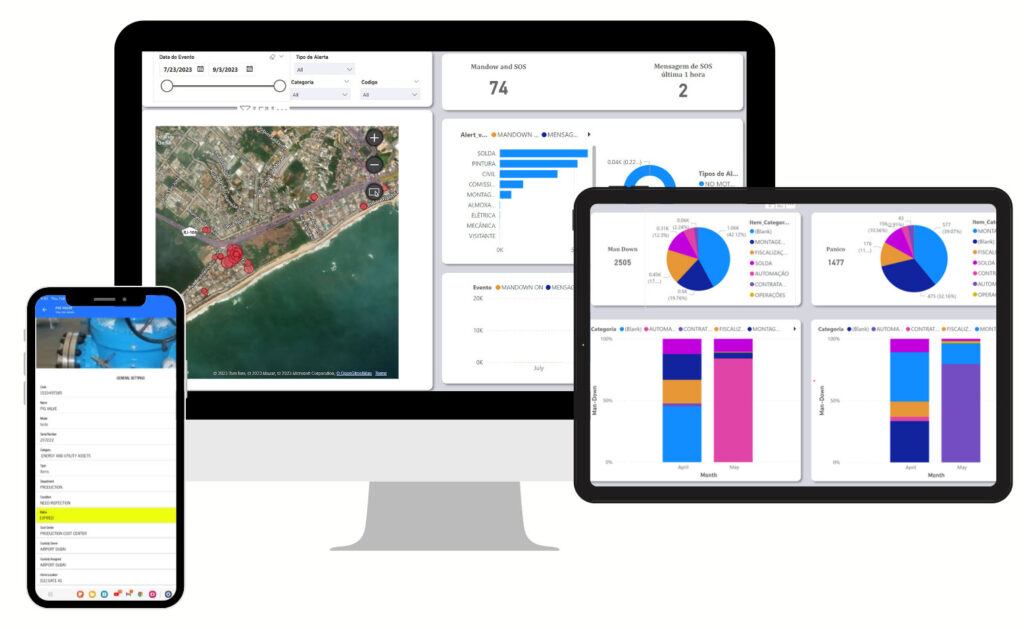

SmartX HUB, also known as SIM (Safety and Inspection Management), is a mobile-oriented application designed to streamline and digitize various aspects of your operational processes.

Serving as an inspection management software, SmartX HUB enables your team to efficiently collect standardized data, pinpoint opportunities for enhancement, distribute reports, and foster collaboration among different workgroups, all through a user-friendly and unified application.

In hazardous environments, the worth of specific PPE and equipment to a worker often surpasses its monetary cost. Organizations dedicate significant resources to maintain compliant and safe work areas. However, relying on paper-based inspections and manual equipment tracking can introduce errors, jeopardizing worker safety and operational integrity. Furthermore, these processes impose unnecessary challenges on frontline teams and site safety managers.

SmartX HUB's Safety & Inspection Manager, or SIM, addresses these concerns by digitizing compliance and equipment tracking. This transformation supports proactive safety initiatives and enhances equipment management, ultimately bolstering safety while alleviating the administrative burdens placed on personnel and safety managers.

Instead of using paper and pen, personnel enter information digitally. This minimizes errors and allows for more accurate data collection. Users can input text, numbers, images, and other relevant data directly into the checklist.

Users can create and customize digital checklists tailored to their specific needs. These checklists can include a wide range of items, tasks, or questions to be reviewed during an inspection.

SmartX HUB provides immediate feedback during the inspection process. It can flag potential issues, suggest corrective actions, or display relevant information to the user based on their responses.

SmartX HUB allows users to attach photos, videos, or documents to checklist items. This is particularly valuable for documenting conditions, issues, or compliance with visual evidence.

Reach your teams, no matter where they are, and always know they received the message. Heads Up makes workplace communication easy by allowing you to create and send engaging messages in seconds.

The digital checklist module can be integrated into existing workflows and processes. This allows for seamless coordination between personnel responsible for inspections, maintenance, and compliance.

The system maintains an audit trail, recording who conducted each inspection when it was done, and what actions were taken. This enhances accountability and transparency.

SmartX HUB can generate automated reports based on the checklist data. These reports may include compliance status, trends, performance metrics, and any identified issues or areas for improvement.

SmartX HUB can be used wherever equipment, components, or tools need to be checked and the results recorded. It helps companies comply with regulatory and statutory requirements, including:

In addition to inspection, SmartX HUB can record and analyze results for tests, including NDT and DT, with automatic data collection via interfaces to testing equipment.

SmartX HUB can be adapted for use in almost any operation where equipment needs regular inspection and records of the results need to be kept. It is suitable for applications such as:

:

Location-enabled devices, linked to a cloud-connected platform, means you can be on the ground to understand what’s happening wherever you are.

Affordable and easy-to-use emergency management solution, customizable to suit any business. Offshore edition also available.

Harness fast incident response. Learn how to detect and respond to any safety challenge with wearables.

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc