- Solutions

- Industries

- IoT Platform

asset management

security

- Resources

Resources

Products

Success Stories

RTLS Fundamentals

- Blog

- About

- En-US

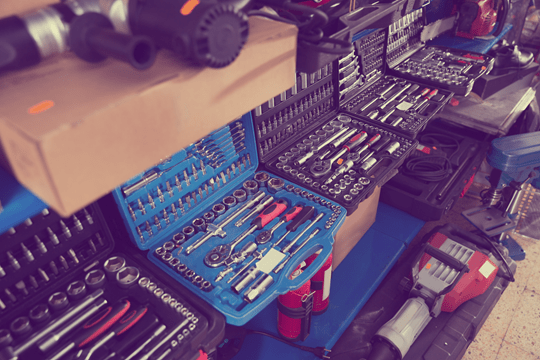

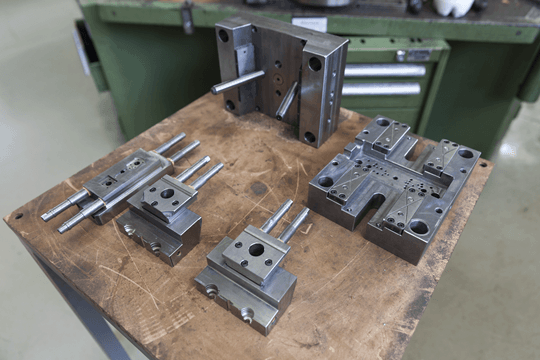

SmartX HUB tool tracking solution uses state-of-the-art technology to help companies in mining, construction, oil & gas, and many other industries quickly and efficiently maintain real-time data regarding tool locations, maintenance history and inventory. The RFID tags we implement are designed to withstand incredibly harsh conditions, allowing your company to take advantage of the massive time savings provided by RFID technology even when your equipment is covered in dirt or grease.

Visit below describes some of the potential applications for our tool control solution:

In its most basic configuration. SmartX HUB Platform comes with a bunch of passive RFID tags and a portable handheld reader.

SmartX HUB Platform allows you to program and commission the RFID tags with a unique ID to identify each individual asset to be tracked. The unique IDs are associated with a record in the SmartX HUB Platform database where additional information on the asset may be stored.

Additionally, each location where tagged assets will be located is marked with a RFID tag created to uniquely identify the location. SmartX HUB Platform is initially set up to know the locations of all assets. The system is now ready for rapid inventorying.

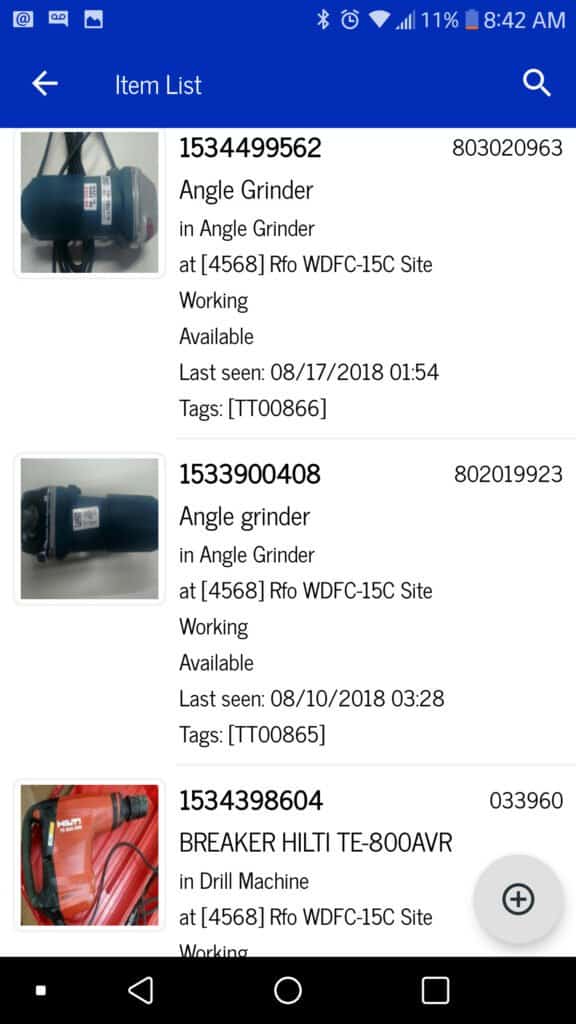

At inventory time a portable handheld reader with SmartX HUB Platform mobile software can be walked around and used to quickly scan for location RFID tags and asset RFID tags much faster than is possible with bar-codes. All the data is collected and wirelessly transmitted to the SmartX HUB Platform server.

This equipment maintenance software monitors and schedules maintenance of items needing service and provides full reporting for service due, outstanding repairs, meter readings, maintenance histories and much more.

Having an equipment maintenance software to track the maintenance schedules of your tools and equipment can benefit your company in a number of ways:

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc