- Solutions

- Industries

- IoT Platform

asset management

security

- Resources

Resources

Products

Success Stories

RTLS Fundamentals

- Blog

- About

- En-US

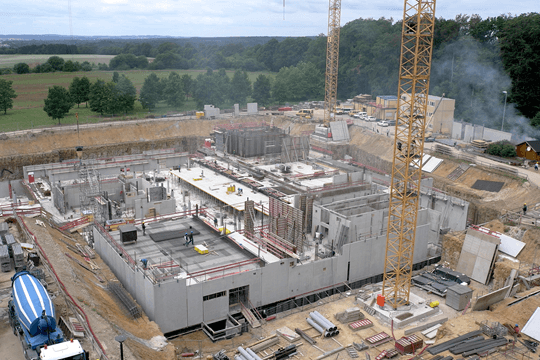

Management of materials is very necessary for the smoothly running any construction project. The most common problems faced by the construction companies are supply delays, material shortages, wastage and lack of storage space. Without proper planning and order, there can be many errors in the projects. RFID (Radio-frequency Identification) can help construction companies in overcoming the issues and frustrations that occur when managing and tracking the materials.

In addition to financial concerns, a plethora of other issues arise when construcions job sites don’t maintain solid records of their assets. The following issues could easily be rectified with a robust asset tracking system in place at these constructions companies:

The traditional methods like paper-based tracking used for tracking materials have lots of problems. The RFID technology helps in overcoming these problems that traditional methods have. There are multiple components in an RFID based tracking system.

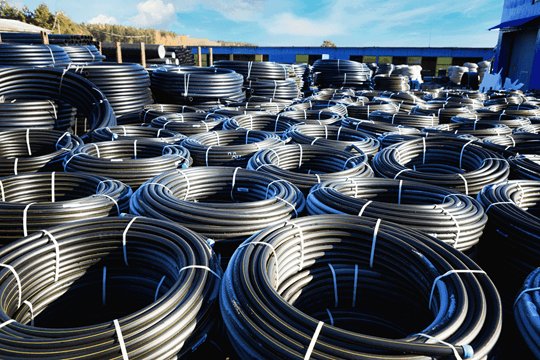

A basic RFID based tracking system contains tags and readers. The tags are attached to the physical materials to be tracked, and the reader communicates the data from the tags. The tags become active only in the presence of the readers. However, active tags are also available, which are active all the time, because they have a built-in power supply. The active is little costly but they also have better readability than the passive tags as they are active all the times.

Using radio frequency, the RFID reader communicates data to and from the RFID tags. The data is then shared with a software system, where it is processed and necessary business decisions can be taken. The RFID tags are placed on the stack of the metal roof panels. The RFID tracking system gives the accurate counts of the panels in the stack. The system is a great way to check the inventory and monitor quantities.

We can also track the location of the panels in a warehouse storage space. In case of multiple storage sites, accessing the materials becomes easy as typing in the information about the item reveal the exact location of the item because it was scanned and keyed in. A different approach will be using different readers attached to different locations.

Systematic analysis of the inventory would also reveal the requirement of the inventory before the construction project starts. The required items can be pre-ordered so the project can start on time, and not be interrupted by having to order the materials in the middle of the project.

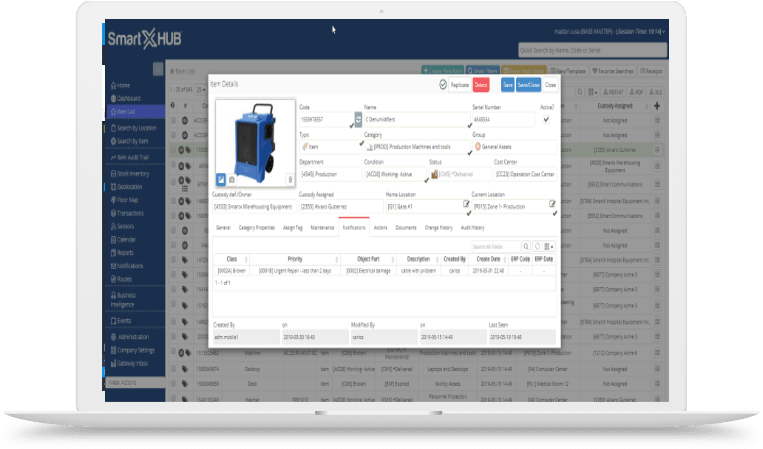

SmartX HUB RFID-enabled software is “compartmenting” which enables the tracking and managing of an entire data center system asset such multi-rack level enterprise switching system or server blade system as a whole & the individual racked components of that entire system.

The system quickly and accurately accounts for checked out equipment by not only reading all the tagged equipment placed on the checkout counter, but also allowing for additional details to be provided at the time of checking out. Additional details could include project and experiment related information. Check-in process is similarly automated.

The SmartXHUB IT Asset Tracking solution:

With the help of RFID, one can improve the predictability of the project estimates. The RFID system can definitely help in the kind of project where the system has been used in one project and then a project of similar scope and size is acquired later. The data acquired from the previous project can be used to determine the material requirement of the new project. This analytics can save a considerable amount of the time and keep the costs down for construction companies.

RFID can be used to separate different type of materials like bulk materials, engineering materials, and prefabricated materials according to the requirements.

Overall, RFID can be used how materials are tracked and managed in the construction industry. As more people know about the benefits associated with implementing RFID technology to track the materials, its adoption will increase considerably. When companies become cost-effective, they can provide better services to customers effectively.

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc