- Solutions

- Industries

- IoT Platform

asset management

security

- Resources

Resources

Products

Success Stories

RTLS Fundamentals

- Blog

- About

- En-US

Manual tracking of pallet contents and inbound/outbound shipments can no longer keep pace with the speed of business. Warehouses must be organized to allow for finding and counting inventory.

Assembling shipments requires verification of the correct item SKUs, quantity, and destination matching inbound and outbound goods. Inaccuracies at transition points, like factory gates doors, where a handoff of ownership and control in the supply chain take place, can lead to increased costs and frustration.

Competitive pressures are growing from year to year:

• With the continued evolution of globalization and offshoring, competitors

are reducing direct material and labor costs, as well as providing innovative new service offerings.

• Consumer “big box” retailers are negotiating low prices and are looking for annual reductions as supply chain efficiencies improve.

• SKUs are proliferating in all industries, as companies compete for shelf space and mind share. Private labels

compete with name brands, promotional SKUs abound, and “mass customization” drives products with millions of configured options.

• Supply chain velocity is increasing, as companies squeeze out inventory by moving from monthly to weekly to daily replenishment cycles, and extended visibility from point of sale (POS) and auto-ID (RFID, bar code, sensor, and others) allows companies to move to more demand-driven processes.

RFID promises to revolutionize supply chains and usher in a new era of cost savings, efficiency and business intelligence. Some of the main benefits of integrating RFID in SCM are: Automatic non-line-of-sight scanning, labor reduction, enhanced visibility, asset tracking, item-level tracking, traceable warranties, and product recalls, quality control and regulation, and ability to withstand harsh environments.

RFID directly affects a company’s bottom line by creating new value in the supply chain, synchronizing the movement of material and products all along the way. It allows companies to:

• Increase visibility into their supply chain operations

• Respond more quickly to real-time disposition and dynamic business conditions

• Reduce errors and labor costs through increased automation

• Increase customer service, satisfaction and loyalty

The SmartX HUB platform uses RAIN RFID to enable wireless connectivity to everyday items such as assets, pallets, cases, returnable assets (like racks and cages), and delivers each asset’s unique identity, location, and authenticity to business and consumer applications.

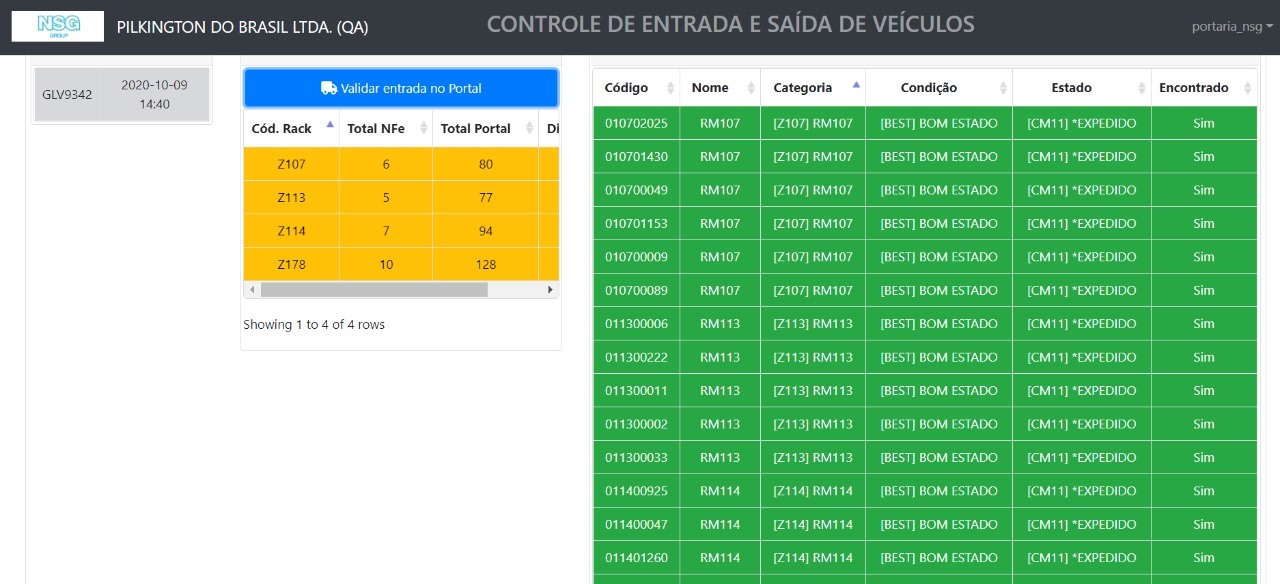

Outbound Shipment SmartX HUB for auto-ID and pallet serialization enables customers to support the basic operating steps required to ship a serialized pallet to customers.

These steps include:

A shipping dock is a place where companies can target investments to derive combined benefits from both labor and space savings. Pallets can be tracked as they move in and out of a facility. By connecting the data about these tracked pallets with the Smartx HUB solution that run shipping and receiving, businesses can automate the shipping and receiving palltes processes in real-time and also gain insights that can further automate processes.

The SmartX HUB platform uses RFID technology to identify pallets (without direct line-of-sight) at a distance of up to 25 feet. By attaching or embedding tags into products and using RFID readers instead of barcode scanners, taking inventory becomes much faster and nearly 100% accurate. RFID can identify and locate up to 1,000 individual items per second. Taking pallets inventory with an RFID handheld reader is 25X faster than with a barcode reader.

The SmartX HUB solutions deliver real-time visibility, creating confirmation or exception alerts, as well as initiating shipping and receiving workflows that are often manually done today.

• Get the right pallets on the right truck, every time: Add RFID tags to individual pallets to ensure that the right goods are on the right truck, every time. Verify shipments against the manifest and automatically alert your team when a shipment is incomplete, contains the wrong pallets, or is loaded on the wrong truck.

• Gain real-time, accurate data about the movement of pallets in your operation: Integrate real-time, pallet-level RFID data into enterprise shipping and logistics applications. You’ll have accurate information that enables your team to make key business decisions.

Organizations large and small and across industries can leverage RTLS to improve safety, safeguard materials and work more efficiently.

Discover how your peers are benefiting from real-time visibility.

©2014-2024 All Rights Reserved. SmartX Technology Inc